Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Norse Woodsmith Blog Feeds

What Do the Words "Modern Design" Mean? Asking for a friend.

Edo period, late 18th century

Edo period, late 18th centuryLast week I visited the Metropolitan Museum of Art - the first visit in awhile. I had a good experience (aside from a supposed upgrade to the coat check that entailed a time-wasting data entry session on an iPad rather than the give-a-jacket-get-a-number standard method).

One of the exhibits I had wanted to see was on "The Infinite Artistry of Japanese Ceramics." As expected, the exhibit was full of pottery, fabrics and wood prints. I was struck by one very nice-looking modern piece. Being open minded, I said to myself, "That's great, they're having some modern stuff along with the old stuff. It's a really wonderful contrast between old and new." But then I took a closer look at this "modern" pottery and discovered, much to my surprise, that was 250 years old! A lot of pieces on display were just like that: modern design in appearance, but in fact actually centuries old. This phenomenon can be a real source of double-takes, because it turns on its head what it means to say "modern" as opposed to "new." After all, usually when talking about design, when someone says, "This is a very modern piece," they also mean it's new and cutting edge. Certain designers like Gerrit Rietveld have designs from the 1920's that don't look dated. But I wouldn't exactly call them "modern." I would say Rietveld's furniture doesn't look like most current furniture that would be considered modern today. In the case of modernist Danish 20th century design, Ikea has commonly co-opted everything, and increasingly anything that's sort of Danish style is assumed to be mass-market and probably cheap junk. But it's not, and it doesn't have to be.

But seeing this Japanese pottery and not identifying the style as modern makes no sense to me. Sure, you can say it's from such and such a period, and such and such an artist, but it still looks modern. Also notable: this style didn't really catch on. Most of the other pieces in the show, some quite beautiful, certainly look of their time period. NYC has several Japanese supermarkets (and Korean and Chinese markets that stock Japanese items) in which some of the same patterns of the not-so-modern goods are still on offer. But we wouldn't call those designs "modern." Is it possible that the word "modern" means "different from the standard of the time" rather than new per se? If the style catches on and everyone copies or riffs upon it, then the style will get its own name. For example, "mid-century modern" defines a specific genre in a specific style. Eventually the style became more accepted, and then more simplified, until it became (in the popular consciousness anyway - and I say this as someone who once owned a Wim & Karen bed) as "Ikea" or "Ikea-style." Rietveld's furniture, nearly a hundred years on, still looks pretty avant-garde. But it never really became a thing. The Bauhaus design movement (1919-1933), which eventually evolved in many respects to mid-century modern Danish furniture, was designed from the get go be be factory made and lent itself to a popular genre - even if later designs aren't directly connected with the Bauhaus. (And perhaps Bauhaus nowadays is best known as the name of the British goth band.) Reitveld, on the other hand, designed his furniture to be made largely by hand so anyone could built his designs from common wood materials. But most of his work would be fussy on an assembly line and his style never caught on.

I'm wondering if 300 years ago in Japan, a potter produced a pot, and his friend said "That's a really modern pot!" and the potter replied, "Yeah, shame nobody likes anything new." That potter used a design vocabulary of his region and most of what he made would be in that design vocabulary because that's what people wanted - the definition of a popular style. Doing anything new and different would make the creator an outlier - and outliers are the modernists of their time. And it seems that, at least back then in Japan, a potter's idea of a modern design would be pretty much what we would call modern today. And now, like then, people still mostly prefer traditional designs (simplified for manufacture) not modernism.

Early 17th century

Early 17th centuryChanging anything for anyone making products is always a risk. You need to convince people that the conventional style, which is by definition what is popular, is just one option, and other options are different and better in a meaningful way. That's not easy to do and this problem has been true from centuries.

N.B. Before you accuse me of drawing conclusions without enough evidence, let me remind you that for centuries archeologists have been postulating civilizations and taxonomy based on the survival of a single bone. So I am in good company! The furniture in museums isn't usually representative of what most people had. Rather it represents what donors and other rich people used - and what managed to survive.

Edo period, ca. 1670-90

Edo period, ca. 1670-90 Cast iron and Bronze. Onishi Gorozaemon mid-17th century

Cast iron and Bronze. Onishi Gorozaemon mid-17th century Happy Year of the Horse from Hello Kitty and Giant Cypress!

Happy Year of the Horse from Hello Kitty and Giant Cypress!

just me and the cat......

My wife left for North Carolina on sunday to keep daughter #2 company while her husband is away on a business trip. The bookcase didn't go but the glass door cabinet did. Supposedly the bookcase is going south on the next trip south. Now I have to get it out of the shop and into the boneyard but that may be a headache. My wife is turning it into a reading room. Translation - I can't use the boneyard anymore for projects.

|

| hmm....... |

From China and there are three 93 1/2" long bandsaw blades. The current blade on the bandsaw burned the cherry bookshelf badly. I had to expend extra calories to rasp and sand it away.

|

| hmm...... |

This sat overnight on the front porch step in below freezing weather. Before I try and use them I'll let them warm up for a few hours.

|

| nope |

Decided to put this away for now. Ace has 2 1/2" hole saws from $30 to $52 which were too much but I did find and order one on Amazon for $10. I'll have it tomorrow.

|

| might be toast |

The burning hole from yesterday may have drawn the temper out of this. I sharpened it and put it away. Two days ago I found a pkg with two of these cutters but I can't find where I put them down.

|

| look at what I found |

I didn't know I had this big ass bit - it is a little more than 2 5/8". That is close enough to the 2 1/2" diameter I need. Before I used it I sharpened it again with my diamond stone paddles. You can see that the machining on this isn't something to write home about.

|

| new insert |

This piece of pine is between rift and quarter sawn, perfect for the insert.

|

| ok.... |

There is about a 16th clearance all around the guide. A little sloppy IMO but I won't have to worry about it binding in the hole.

|

| insert ready |

The bushings fit in a 5/8" hole. The top of them is shouldered and that is acting like a stop for them.

|

| sigh.... |

Put the cart before the horse. I missed sawing the insert to length before drilling for the bushings. On to insert #2.

|

| got it |

The fit is snug. After I drilled all the holes, planed it for a drop in fit.

|

| lid |

I sized the lid to be almost a dead on flush match with the outside of the box. I did this because the plan is to put a rabbet on the underside of the lid to fit in the inside of the box.

|

| Lie Nielsen skew block plane |

Ran a knife line 360 and planed down to it until I removed it. Did the end grain ends first and then the long grain sides.

|

| not an oops |

The length fits well. It dropped into place with no binding and no slop neither. However, the width doesn't fit. I planed the rabbet shoulders with my 1/2" shoulder plane. The pencil line on the lid is what I thicknessed the lid down to - 3/8" after fitting the lid.

|

| hmm...... |

I chamfered the edges to soften them. As of now, I don't plan on putting a knob on the lid or making a finger access divot.

|

| lid is done |

Didn't like the chamfered look so I sanded them to a round over.

|

| not enough |

I wanted to use walnut dowels for the contrast with the cherry but it ain't happening today boys and girls. Thought of using birch but went with cherry.

|

| finishing the ends |

I had sanded the outside of the ends up to 220 but there were scratches left from the flush cut saw. Scraped them away with a card scraped.

|

| gotta save this |

I was going to cut the back slats and the shelf off but nixed it. The shelf would have ended up with a width too narrow but the length would have been ok. Decided to try and salvage it somehow.

|

| hmm....... |

Sawed two 7° wedges and put them under the feet. The shelf is tilted up and back and the sneakers on the legs don't look wonky IMO. It is just a concept and the only hiccup I see is the back sneaker is a little on the thin side. That could be a potential breakage point.

Another headache is the orientation of the grain on the sneakers. The end grain side is against the feet. I had to make two more sets that had the long grain facing up against the feet. Doing that was bit of pain in the arse. None of the do dads I had for setting an angle worked - the 3/4" thick stock wasn't thick enough to lay out the angle.

|

| better |

I don't know what this angle is - I laid it out from the left bottom corner with the angle going up to a end point 6 1/2" away. This fix is growing on me and I'm thinking of keeping it.

|

| squaring it off |

This almost gave me a headache trying to figure out how to square this end off to saw. I could have sawn the angle to match the front edge but I wanted it squared off.

|

| hmm....... |

I think this is the way to go. The sneakers on the bottom look deliberate.

|

| that is an option |

As I was getting ready to kill the lights this popped into the brain bucket. Cut/saw the sneakers to match the length of the back and front feet plus a 1/4". Maybe even follow the curve of the cutout into the sneakers. Time to think about it over night.

accidental woodworker

a link to the woodworking stuff, otherwise birds

I’ve been carving stuff in the shop, some panels and the beginnings of two more strapwork boxes, one white oak, one walnut. All sawn stock, my riven oak is just beginning to poke out from under the snow. Today’s post on the substack blog is free-to-all subscribers (paid & free) – there I talk about some period carvings and post a couple of carved panels for sale…

https://peterfollansbeejoinerswork.substack.com/p/more-about-carved-panels-plus-video

But I’ve been wanting to work some recent bird photos into my everyday blog, just haven’t had much room. I have too much to say about the woodwork. The winter weather has brought some of the raptors in closer, some of them have a hard time finding food in the snow, so the bird feeders bring possible prey into view for them. That’s how I read it anyway. I know it’s true of the cooper’s hawk (Astur cooperii) – this one snatched somebody from around the bird feeders, then fed up in the top of the apple tree.

While I photographed this bird from the open back door, I saw a larger raptor swing by – just turned the camera quickly, thinking “I’ll get this red-tail…” – turned out to be a bald eagle (Haliaeetus leucocephalus) –

we don’t often see them here, but the river was open water – most of the ponds around here are frozen over. He was gone in an instant.

Another day another raptor. Thought I saw two more red-tail hawks flying over the house…they too were gone in an instant. Then half-hour later, saw two hawks perched in the sycamore tree next door – but they were red-shouldered hawks, not red-tailed hawks. (Buteo lineatus) – I couldn’t get them both in the same shot – this one posed more cooperatively than the other.

Down in the river one day saw these buffleheads – the smallest duck. (Bucephala albeola) –

these are females and for a little while I worked myself into a state of confusion by mis-reading Sibley’s book about the bufflehead. What I thought I read was that the male doesn’t show his breeding plumage in the winter…which is not the case. Doubly-so. Not what the book said, not what the duck does. I know I’ve seen many breeding-plumage male buffleheads over the years – but they breed far north & west of here. Far. Below is a shot from the same river, same backyard, almost exactly a year ago – one male, two females. These birds are pretty skittish, I can never get close to them.

My birding mentor Marie helped sort me out. Momentary collapse of reading comprehension. It happens.

The red-tail hawks (Buteo jamaicensis) are around regularly – this one, a juvenile – tried to snatch someone from the feeder-crowd. Missed, then perched in the catalpa tree right outside the shop. Often you can get near juvys for good shots –

Every snowy winter we try to get a good photo of the northern cardinal male in the holly tree. I didn’t get it just right this year, but got a consolation nice shot of the female – (Cardinalis cardinalis)

In the winter, there’s often 10-12 cardinals here at once, but I can’t seem to get a group shot that’s worth a damn…so here’s a male portrait from quite a few years ago – next to the holly tree…

one down, two to go........

|

| layout |

Took my time and got it right. What I have to watch for is the back slats. I have a bad habit of laying them out on the wrong edge - the layout on the ends are mirror images. It is very easy for me to wander out into La La Land doing it. However, I haven't had chopping out brain fart for quite some time. I have caught my layout me-steaks by double, triple checking myself.

|

| left or right end????? |

It is self supporting but I was working on getting the front end of the dado gap free. Noticed that my walls weren't dead on plumb and it was keeping it from being gap free.

|

| bit of a gap |

This is the end panel where the dado wall wasn't plumb. It took me a few chisel/trim and checks before it closed up. I was shooting for it to be gap free with hand pressure but that didn't happen. It easily slammed shut with clamp pressure.

|

| helping hand |

I try to avoid using these clamps because they are a ROYAL PITA. I have problems with tightening them fully before running out of screw length. However, for this application they are a perfect fit due to the clamp head staying parallel to the clamp bar. And they closed the gap nicely.

|

| first back slats fitted |

Happy with how well this fit. I laid out the notches a wee bit undersized so I would get a snug fit. I was shooting for a seamless fit between the slats and the notches. I didn't want to do shouldered tenons - I like this look more.

|

| the left one |

Three of the slats fit snug/tight and this one is kind of snug. It is self supporting but it is looser than its siblings. I think it will be ok and I expect the glue will swell the joint tight.

|

| dry fit |

Happy with this and especially so with the fit with no hiccups to rant about.

|

| view from the back |

Thinking of leaving the ends as is and making the top parallel to the bottom. Initially I was going to do them like the pine bookshelves but I came to a fork in the road.

|

| hmm..... |

I was going to round the two outside corners on the shelf but I changed lanes again. I like the look of the corners clipped more than them being rounded. I was going to round them because I did the tops of the ends like the pine bookshelves.

|

| glued and cooking |

I didn't forget to drill holes first for the Miller dowels. Been running through the brain bucket whether to use cherry or walnut dowels? I had to swap clamps because I couldn't get the Besseys to close the gaps at the front. Used a 24" bar clamp to do the job.

|

| look at what I found |

Came across these and I had totally forgotten I had it. 90 degree drilling guide for flat and round stock. 6 bushings, three imperial 1/8", 3/16", and 1/4". Three metric at 3mm, 5mm, and 8mm. It is something I could have used recently. Since I had time on the clock before the quitting bell rang, decided to whack out a box to keep it in.

|

| still kicking my arse |

I have had this circle cutting jig for 40 years. For years it has made me feel like my IQ isn't in double digits. I still haven't figured out how to orient the cutter in the arm. But the biggie is determining the diameter of the circle. There is a scale on the arm and I set it for a 2 1/2" diameter circle and I ended up with one a little over 2 3/4".

|

| first hole |

The empty part matches the diameter of the guide spot on but the overall diameter of the hole is a 1/4" too much. On the 2nd attempt, I got a burned out hole. The insult was it was too small.

|

| hmm...... |

I drilled this one coming from both sides, and both sides burned equally bad.

|

| heebie jeebies setup |

I'll be doing the next hole drilling differently. I will use an oversized board (length wise) with that one. I am also contemplating using a 2 1/2" diameter hole saw. I have a 2 1/4" and a 2 3/4", sigh. But that depends upon the cost. If it is too much I'll expend the calories and figure out how the circle cutter jig works once and for all. If that doesn't happen free flying lessons might be in its future.

accidental woodworker

Why the Longer Posts, Paul?

cherry bookshelves........

The plan today was to thickness the cherry for the new set of cherry bookshelves/CD/DVD holders. That didn't happen boys and girls because of two hindrances. The first was the snow between me and the stand for the lunchbox planer. It would have probably taken me a bazillion years to shovel a path to the garden shed] to get it.

The second one was the weather. It was supposed to be partly sunny but the entire day was cloudy. To me there was a threat of rain or snow but the weather seers predicted neither would happen. I wimped out and opted not to plane the cherry today.

|

| close, but no cigar |

Only got 3 coats of shellac on these. My limited attention span took a left turn to concentrate on thicknessing the cherry. The photo dots aren't supposed to be here until tomorrow. I have plenty of time to finish them up.

|

| the extra bookshelf was the lead off |

Decided to thickness the cherry by hand. I only had to do a couple of pieces with the 3 sets.

|

| not quite |

I used the tablesaw to saw the cherry as deep as I could. There was a 1/2" web that I used hand saws to separate. Started with the Ryoba and switched to a 7pt rip saw.

|

| sigh |

The two halves have divots on this end. The right board has another one on the opposite end. I planed and smoothed the two but the divots remained. To plane the divots even would leave them too thin to be shelves.

|

| hmm...... |

Thought of putting this face down but I nixed that. The shelf tilts up and it could be visible. These two are toast but I can use them for a box or something else.

|

| the fix |

This is for the extra bookshelf and this is the new shelf for it. I needed to plane a little more than a 1/8" off to get to finished thickness.

|

| done |

Planed the ends a wee bit to thin their thickness too. Got the shelf and ends done (after I saw them to length) and they are ready to go.

|

| looks good |

Eyeballing the thickness of the shelf against the thickness of the ends. I made the thickness difference between the them all 1/8". The ends are 7/8", the shelf is 5/8", and the back slats are a 1/2".

|

| the grandson's bookshelves |

These two are ready to layout and start chopping dadoes and notches. I will make the extra one first and then attack these two.

|

| sigh |

I didn't know that one of the cherry boards still had a rough sawn face. I knifed a line 360 and planed down to it.

|

| finally done |

Planing cherry to thickness isn't difficult but not as easy as pine is. It seemingly took me forever to plane down to the knife line. Glad this was the last cherry board to thickness. It took me almost all day to do this. Pleasant way to eat up the hours.

|

| the extra bookshelf |

I like the slight graduations in the stock. I wavered a wee bit with the ends thinking they were too thick. I thought they might be clunky looking because they aren't that tall. Seeing all three together squashed that.

|

| confirmation |

This looks good to my eye. The back slats won't be visible with a fully stocked shelf so they don't matter that much. However, the 1/8" difference between the ends and the shelf is just right IMO.

I ordered new bandsaw blades - that is why I didn't try to resaw the cherry on the bandsaw. The blade on it now is having trouble sawing wet paper. I bought 3 of the cheapest blades I could find on amazon. As long as they last to do the sawing for the 3 bookshelves I'll be a happy camper.

accidental woodworker

A bit of Whimsy and Milk Paint: Frame #280

Once Upon a Time

Once Upon a Time

Corner Detail

Corner Detail

Here’s the most recent frame from my shop and it was fun to create so thought I’d share the story! It’s oil on canvas measuring 12″x16″ and by my wife, Diane Eugster. When I first saw it in her studio my mind went to a wood nymph; whatever that may be! This painting needed something other than a traditional black/gold frame, something more fun and maybe with a bit of whimsical carving to enhance it.

Creating the Profile

Creating the profile began with my typical Basswood sized approximately 1″ thick by 2 7/8″ wide. The process begins by cutting the backside each pieces at 15° to create a profile that angles the frame away from the wall leaving plenty of room to install a 3/4″ thick canvas. I refer to this as my 15° Profile and it’s a way to angle the frame. I wrote a BLOG about it some time ago. I’ve modified the process somewhat since then but that blog gives you the basic method to do it. It took me less than 2 hours to profile this frame, carving took much longer than that.

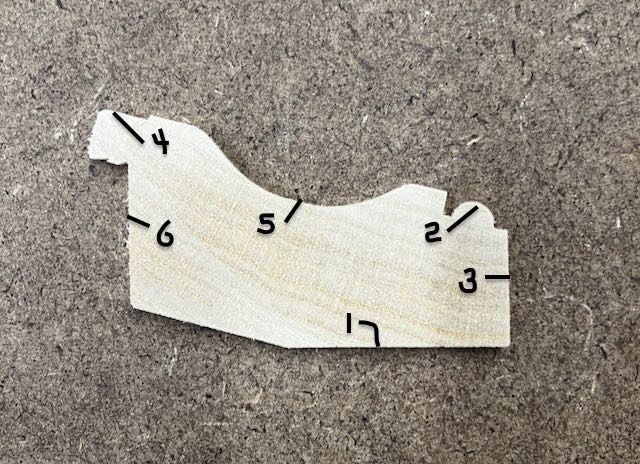

The process began with cutting the 15° angle on the back of the piece, that’s #1 in the picture, this will become the outside edge of the frame. If you do any beading on the frame it’s important to do that before cutting the outside edge 90° to the angled cut. This makes it easier to clamp when gluing the frame together. For this profile I cut a 1/4″ bead on the outside edge, #2 with a small plow plane. Draw a 90° line (#3) from the angled cut to locate the outer edge of the bead. This piece will be cut off after the bead is complete. For this profile I wanted a flat section at the sight edge for gilding, this is #4 and was created with a skewed rabbet plane. To create more interest to the frame I also cut a cove; #5. This was done with a tablesaw, it’s an interesting process and I wrote this BLOG explaining my process. The final cut is #6, the rabbet. This is somewhat tricky so check my blog on how to do it. Very important to note that I always have at least one extra piece of stock about 10-12″ long to set up the tablesaw for all of these cuts.

Carving

Not exactly sure what these are called, they look like an elongated bead or a sausage but I’ve seen them called either billets or reels. To figure out the spacing it’s easiest to use a set of dividers and step the divisions off once you decide their approximate length. Do that on a piece of masking tape, not your frame because there’s a lot of trial and error involved and your bead would have all the markings from the divider. Once you’re satisfied with the spacing put the markings on the frame. My preference is to start at the center and work to the ends. Any slight error will show up at the ends only. I used a 1F/8mm skew to divide them, then a 8/6mm gouge to create the rounded ends. Finally a 1S/5mm removes the bits between the reels.

Finishing

I’ve been using milk paint from RMPfinishes (formerly Real Milk Paint) lately to finish some of my frames. I like the effect of it and it comes in a powder form. That means I only mix up a small amount as needed and the powder will keep forever unlike paints that come in a can. For this frame I chose Blue Spruce. I mix 2 ounces of powder with 2 ounces of distilled water and that’s enough to complete the frame. I’ve found that the foam brushes they sell work great, much better than those available from my local big box store. I lightly scuff between coats (2 usually) with a Mirka 1500 pad. This frame has a gilded, silver sight edge so that was taped off and applied with quick set size. Milk paint should be sealed and I’ve used wax, OSMO #3043, and also Platinum Blonde Shellac which I spray on with an air brush. That’s how this frame is sealed, the shellac also seals the imitation silver leaf. The final step is rubbing out the shellac with Liberon wax to take some of the sheen off of the shellac and even out the spray pattern from the air brush.

Blue Spruce Milk Paint

Blue Spruce Milk Paint

Quick set size for gilding

Quick set size for gilding

That’s the process for this profile; in my opinion, adding the cove and the carving creates many shadows and patterns that brings interest to the frame.

Ultimate rippeled Gidgee

good day's output.......

My wife had a paving contractor come to the house today to give us an estimate on getting the driveway repaved. 30 minutes later we had a contract and he had a check for $2100. That deposit locks in the cost of the base stone and the paving. We are scheduled to have it done in the 3rd week of April. It is a one day service and we can walk on it right away but can't drive on it for 3 days.

|

| checking the cherry |

I had flattened/thicknessed all the cherry before but I am starting over with it again. Most of the boards were still twist free, a couple had a wee bit that I dealt with. The only other hiccup were a couple of them had a hump in the middle.

|

| yikes |

I was holding the off cut side too but it still decided to be PITA. This board was giving up two shelves.

|

| hmm...... |

This is too big of chunk to saw off as it would shorten the length of the shelf too much. As is the shelf is 16". If I cut off the boo boo it would about 12" which I think is too short. I glued and clamped it and set it aside to cook. I was pretty happy with how well the it fit when glued.

|

| hmm....... |

This board will give up the four ends for two bookshelves. Used the japanese saw - cross cut went smoothly and easy peasy. No break out on the exit cut. On the one above I did the cross cut with a big sash saw.

|

| almost complete |

Got the 4 ends and two shelves. Just need the four back slats.

|

| hmm....... |

Eyeballing the left over cherry I can see I have enough for one more small bookshelf/CD/DVD holder. In for a penny, might as well be in for a pound, eh?

|

| back slat stock |

I could just plane this stock to thickness but IMO that would be a waste. Two boards are 7/8" thick, one board is 1" and the last one is 3/4". If I can resaw the 1" board in half that you give me two 1/2" thick ones, I can get eight back slats from it.

|

| resawing is next |

The board is two frog hairs thicker than 1" so if I behave I should get two 1/2" thick boards out of this. I will be happy with stock that ends up 7/16" strong.

|

| sawn in half |

I wasn't going to attempt sawing this board in half whole - the length was 32".

|

| not good |

There are some fairly long end checks here to deal with. The longest crack/split ran a little over 3". The checks only appear on this face, the other one is clear and clean.

|

| nope |

I tried to resaw it with the Ryoba but it wasn't working in my favor. The back/exit of the saw cut was wandering. I tried to correct for it but couldn't. Resawed them on the tablesaw and saved it. The tablesaw blade sawed right through the wandering handsaw kerf and erased it.

|

| the result |

Got two at 3/8" thickness and two at a 1/2". I won't have to run these through the lunchbox planer neither. The thickness is a frog hair under a 1/2". Should be more than stiff enough to hold its shape - the length of them will about 14" - 15".

|

| resawed one more board |

Got enough stock here to make eight back slats. I need 6 with two extras for any potential oops.

|

| complete |

This will do for making the grandson's bookshelves. I'm leaning towards making the R/L of them smaller than the pine ones. Maybe 14-15" - there isn't much call for reference books anymore because of Google.

|

| the one more |

It still is a little surprising to me that it takes very little stock to whack one of these out.

|

| where is it? |

I eyeballed this for several minutes and I can not see the glue line on this. Nothing shifted on me when I clamped it up.

|

| the side edge |

Couldn't pick it out the edge neither. This edge blowout had two long, thin pieces and it glued back together seamlessly. The board is 3/4" thick and the plan as of now is to plane it down to less then 5/8" and more than 1/2".

|

| not too bad looking |

I have some photo dots coming from Amazon. They are basically dots of double sided tape made specifically for securing photos.

|

| almost done |

Need to slap 4-6 coats of shellac on the backs. Got two on before I killed the lights for the day. I will come back after dinner and get at least one more. I'll finish up the shellac in the AM.

accidental woodworker

Leaf Pattern Shrink Pot

it's warming up.......

Don't have anything in the pipeline, not even a thought. My truck is going in the shop for repairs on monday and tuesday so I'll be without a vehicle. The plan as of this typing is that I'll be motoring up to Highlands Hardwoods in New Hampshire on wednesday or thursday. That is weather dependent too. I am going to make the grandsons their desks one at a time. Hesitant to buy enough cherry for two but on the other hand it will mean another round trip up north. Decisions, decisions.

|

| done |

Six coats of shellac before the shine was acceptable to me.

|

| hmm...... |

Rethinking the bookshelves I just made for the grandsons. I have enough cherry here to make two bookshelves. The pine might be too much of a contrast against a cherry top. Looking ahead two smaller cherry bookshelves would melt into the cherry desks. I can plane the cherry to thickness with the lunchbox planer on monday.

|

| hmm...... |

Found out today the bookcase ain't going to North Carolina this sunday. My wife is only taking this wall cabinet with her. I noticed that one of the shelf pins wasn't seating in the notch. I widened all the notches in both of the shelve boards just in case - expansion/contraction is different in North Carolina.

|

| huge difference |

This bottom slat is the one I wanted to add a veneer shim to. No need because it swelled almost shut with the glue.

Didn't get much shop time today. Spent a good portion of it running errands and helping my wife with dead people stuff. Just as well as I didn't have anything to make wood dust with.

accidental woodworker

Some New (To Me) Tools from the PAST Show

At the end of January, I went to the PAST tool collectors show in Fremont, CA. Usually I don't come home with anything, but this time I did grab a few things. I'll show them below, but first let me show this router plane display that one of the guys brought!

|

| A collection of mostly craftsman-made router planes |

None of these planes was made by Stanley or Preston or Millers Falls, or any other maker that we typically think of when we think of router planes. These were mostly user-made tools and they were pretty dang cool. The longest one was 14" long.

On the same table was also a display of an unusual Disston saw - a #196 "docking" saw.

|

| Disston #196 Docking Saw |

There's nothing about it on the Disstonian Institute site, but some other search results indicated it was used for heavy construction, like timber framing or railroad work. It has crosscut teeth and a heavily breasted tooth line. Someone at the tool show suggested the name came from its use on the docks, perhaps crosscutting dock boards to length. The metal handle was interesting - possibly due to its getting rough use.

Anyway, moving on to what I picked up ...

A couple years ago I bought two larger auger bits - 1 1/8" and 1 1/4". I found a 1 1/2" bit at the show and grabbed it for $10. It's a Snell's-Jennings bit, no idea when it was made, but it was in near perfect condition. It was already sharp - both spurs and both cutting lips. And when I got home and made a test hole I was very impressed at how clean the entry rim was. This was a great find because I have had some trouble using expansive bits for larger holes.

|

| A beautiful, clean 1 1/2" hole |

|

| SNELL'S JENNINGS' 6 |

|

| That's a really clean hole! |

I'm a sucker for incannel gouges. One of the sellers had a table where everything was $8. There was a box filled with chisels of all types and I grabbed four - two small incannel gouges (that will add nicely to the larger ones I've got), a bent gouge, and a 1" bevel edge chisel.

|

| The lineup |

The two incannel gouges were from Spear & Jackson and New Haven Edge Tool Co. I just need to clean and sharpen them and I think they'll be a great addition to my shop.

|

| SPEAR & JACKSON SHEFFIELD |

|

| The S&J was about 9/16" wide |

|

| S&J curvature approx 9/16" radius |

|

| NEW HAVEN EDGE TOOL CO. |

|

| About 7/16" wide |

|

| Curvature of 9/32" radius |

The bent gouge is from Ulmia. It's 13 mm wide with an approximate 1/4" radius curvature. I don't do much carving, but this one will be a nice addition to the carving set.

|

| ULMIA |

|

| It's about 1/2" wide |

|

| This shows the amount of bend |

Finally, there was this 1" socket chisel. I don't need another 1" chisel, but this one is a T. H. Witherby. If their chisels are as good as I've heard their drawknives are, this will be a real winner! It's got a little pitting on the flat side, but I think I'll be able to get that out. I found a good article about Witherby by Brian Welch here.

|

| T. H. WITHERBY WARRANTED |

|

| You can see the pitting here |

|

| Not sure why, but I do prefer socket chisels |

That's it. Some nice additions to the shop. Now I have a little work to do to get them up to working condition.

Holdfasts, Every Woodworker Should Own a Set!

A Favorite New Technique

“Your book is next.” These welcome words greeted me a few days ago as I opened my email. Megan Fitzpatrick is my editor, Lost Art Press is my publisher, and my book may see the light of day sometime soon. Sure, there’s still lots of editing and formatting for Megan to do, but it’s begun in earnest now.

One of my favorite new techniques that I learned during the book-writing process was boiled joints. I’ve written about them before, but here’s a clip from my talk at the Working Wood in the 18th Century conference at Colonial Williamsburg a few weeks ago, showing how they’re done:

I just this week learned how to edit videos. This is my first, and I’m rather surprised at how simple and fun the process is. Maybe more will come.

The post A Favorite New Technique first appeared on Elia Bizzarri - Hand Tool Woodworking.long day......

The day started with me finding it had snowed again overnight. Because of that the driver for the shuttle to West Roxbury was late and we didn't get on the road north until after 0600. In spite of that and the crazy Boston traffic, I was only late for my appointment by 4 minutes.

PET scans are easy but they take time. First I had the zoomies IV'ed into me and that took 46 minutes. Then I got to ride the big donut scan for 16 minutes. They stuck something under my legs and had to keep my arms out stretched straight back. That hurt and I had an incredible urge to cough that I had trouble suppressing, but I did because I didn't want to repeat the donut ride.

My shoulders were aching and my hip was humming arias. The nurse had to help sit up and get off the bed. Other than these minor annoyances the PET went flawlessly. Hopefully I won't have to go back to the W Roxbury VA for another PET scan.

I got back home at 1440 and got the garbage ready for pick up in the AM. After that I headed to the shop because I had 20 minutes before the quitting bell ringing at 1500.

|

| from leave book, take a book at the VA |

I had read a couple of articles on this lady code breaker. Since I didn't get picked up to return to the Providence VA until 1250, I started reading it. I got through 80 pages before pickup and I brought it home. Biographical novels are my favorite books to read. I'll be finished with it before the weekend ends.

|

| why not? |

The idea at this time was to steel wool the two bookshelves and apply shellac after dinner.

|

| hmm....... |

I got 4 coats on the bottom and the ends. All that is left to do is the interior. I applied another coat on the bottom and ends again. I did that because the bottom didn't look shiny enough to my eye.

|

| quit at 1538 |

I kept on going boys and girls. I applied the first coat of shellac on the interior. And I will return after dinner and slap another one.

accidental woodworker

Roughing Out

Even on a treadle lathe, the roughing gouge throws off tons of thick shavings

Even on a treadle lathe, the roughing gouge throws off tons of thick shavingsRoughing out is the first thing you do on a lathe project, when you take a square piece of wood and turn it round. You want to do this fast. Surface finish is not that important, although you don't want a disaster. Since the wood is square, you are at least starting with interrupted cuts.

l-r: 1" Continental Gouge, 3/4" Roughing Gouge, 1/2" carbide insert tooling

l-r: 1" Continental Gouge, 3/4" Roughing Gouge, 1/2" carbide insert toolingI have three tools that I can use for roughing out (above).

A continental gouge. If you look at early catalogs, you'll see that essentially they offered two kinds of tools: what we now call the continental gouge, and a typical spindle gouge. Mine is a 1" continental gouge.

A roughing gouge. This is the standard tool people use for roughing nowadays. I have a forged 3/4-in roughing gouge. I also have a much larger one that is really overkill and too big for a machine of this power. This tool is forged because of its size. Ashley Iles and other companies also make machined roughing gouges in smaller sizes.

Insert tooling carbide square edge scraper tools that can be used for roughing as well. Many people prefer the insert tooling carbide scrapers because the learning curve is easier. I bought this tool and a few other carbide insert tools because I've gotten a lot of questions about whether they could be used on a treadle lathe.

In truth, I have a fourth tool that can be used. If I wanted to, I could use a regular spindle gouge and it would work fine - though slower. I left the spindle gouge out of the demo because I would use it only if it were my only option.

A roughing gouge is the most popular tool for this purpose but the question is: for a treadle lathe for which makes the most sense.

l-r: scraper, continental gouge, roughing gouge

l-r: scraper, continental gouge, roughing gouge In the picture above, you can see the results of all three tools with the tool used underneath it. All this work was done with each tool in under a minute - maybe even under 30 seconds. I developed a sense of how fast they cut - and we can see the quality of surface they leave behind. I used all tools with about the same amount of pressure and force. But not enough to overwhelm the machine. The wood is soft maple.

From left to right:

The carbide scraper. My least favorite tool of the three, because it leaves such a rough surface. But it was dead easy to use. You take the tool, you hold it horizontally, and just feed it with moderate pressure, and it wastes away the material. It's exactly what a roughing tool is supposed to do. My only complaint is that there are splinters on the edges of the cut. On harder materials, I would guess it works better; on softer materials you would have a worse, rougher surface.

The continental gouge is historically the oldest design of the group. It is basically a wide, shallow gouge with a slight curvature to the face of the gauge. This particular one is one inch wide and a joy to use. The tools roughs out well and is very easy to control. While not as fast cutting as a roughing gouge, it allowed me plenty of control. The final surface was pretty good. It's also a versatile tool because you can do a lot of finishing cuts with it.

The three quarter inch roughing gouge on the right differs from both a spindle gouge and the continental gouge in that its front is sharpened straight across and the sides go up high and vertical, so they can slice interrupted grain cleanly. The tool profile is more of a "U" than a gentle curve. What you get is a tool that produces very thick shavings very quickly, and makes short work of turning a square billet round. It also is a very reliable tool in that you don't have a sense that you're about to fall off the edge of the Earth or anything like that. It certainly cuts faster than the continental gouge. As you can see, it leaves a reasonably clean surface.

I think the Continental gouge is a very versatile tool. Even when you're not roughing, it takes nice wide shallow cuts. But in terms of actual roughing, the roughing gouge is the winner. I just didn't like the square scraper: the surface it left is rough. I didn't feel the need to use a scraper since I didn't have trouble with the gouges.

If I were a more experienced turner than I am, I would follow the roughing gouges work with a skew chisel to create a perfect cylinder with a perfect surface. Neither the continental or roughing gauges really chew up your surface, so there's not much material to remove to get something perfect. Since I'm less than experienced turner, I find having a fairly decent cylinder from the Continental gouge to be actually quite nice.

If I were doing smaller work, my guess is a less aggressive Continental gouge might be a better choice, although all of these tools come lots of sizes, including pretty small tools meant for pen turning. If I only had one roughing gouge, I wouldn't want one too much smaller.

The most important takeaway from this experiment is that - as in most areas of woodworking - many different options work, provided that the tool is sharp. While there are cases in turning where something won't work well - for example, using a spindle gouge inside a bowl - overall you could do an awful lot of turning with just a spindle gouge and either a roughing gouge or continental gouge (just make to it easier). The most important thing I did during this test wasn't learning some secret technique handed down by turners since 1642. Rather it was making sure my tools were sharp and of the correct geometry when I sharpened them. I am spending time at the lathe nearly every day and as my experience grows and my technique gets better, my turning is naturally improving. I am going faster with far fewer catches and slip-ups.

The continental gouge on the left is ground with the nose sticking out slightly. The roughing gouge on the right is ground square

The continental gouge on the left is ground with the nose sticking out slightly. The roughing gouge on the right is ground squaredone......

The bookshelves I made for the grandsons are done. I just have to apply the shellac. It won't be finished today. Tomorrow I have a PET scan at the West Roxbury VA at 0800. I don't think I'll be getting any shop time on wednesday. I'll have to get up at oh dark thirty (0430) to catch the shuttle from the Providence VA to the West Roxbury VA. Don't know zip about when the shuttle returns to Providence?

|

| one down, one to go |

Came back to the shop after dinner and got all the Miller dowels installed. A final sanding, knock back the arrises, and this will be ready for shellac.

|

| I like it |

I added another dowel on the shelf. When I had glued it up I had to clamp the middle of the shelf to pull the end in tight. Added a dowel in the middle to keep it that way.

|

| surprise |

Got two 6mm fine nuts and one 6mm fine wing nut. I wasn't sure that ACE sold metric fine threads and the wing nut totally surprised me.

|

| nope |

There isn't sufficient room for the wing nut. If I tighten the big screw down as far as I can, I then can't turn the wing nut. I liked this option because it is toolless.

|

| 10mm open end wrench |

I have had this wrench for a bazillion years and I have absolutely no idea why. Finally have a use for it - it is the size needed for this nut. This worked and the iron didn't slip/loosen/change when I used it on the back slat mortises. I tossed the wrench in the box with the router.

|

| not my best |

Three of the mortises were slightly oversized, it would seem I didn't reach under the back slats enough when I marked them. The back slats weren't snug. One back slat wasn't self supporting on the cheeks but was on the top/bottom. This one will definitely need Miller dowels to keep it together.

|

| hmm....... |

The shelf was self supporting - the right one gave in to gravity. The clamp was to ensure that the shelf fully seated in the dado at the front.

|

| the worse one |

A piece of oak veneer (the thickest I have) it just a frog hair too thin. The top/bottom of the slat will pick up the end but gravity wins. I'll glue this in when I glue up the bookshelf.

|

| glued and cooking |

The center bar clamp on the shelf didn't pull in the ends as much as it did on the first one yesterday. In spite of the loose back slats I didn't have any headaches gluing and clamping this up.

|

| chamfering the feet |

I let the bookshelf cook for a couple of hours before I took the clamps off and installed the Miller dowels. I forgot to put the veneer in but the back slat swelled and the gap closed up. Unexpected, but I'll take it and move on smartly.

|

| done |

A little premature but they are done and will be ready to go when I make the desks.

|

| pretty good match |

The sizes of the parts are all identical. I used the end of the first one to layout it out on the second one. The only thing that isn't the same is the back slats on 2nd bookshelf are a 1/4" closer to the back edge of the ends. On the first bookshelf the front edge of the back slats is aligned with the back edge of the shelf.

The three frames are at the Frame it shop. Based on what I saw in her shop, I'll check on them at the end of the first week in March.

accidental woodworker

Ouch.......

My truck failed the state inspection. I knew that was going to happen because I had long crack in the windshield. What I didn't know were the problems with the control arms and the back brakes plus a few other minor headaches. Total estimate is $1600 but that is dependent upon how bad the rear brakes are.

|

| shelf dadoes first |

The goal was to get this glued and cooking today.

|

| done |

Three coats on the back and four on the front. They are ready to go to Maria in the AM.

|

| left one self supporting |

I've come a long way since I starting chopping dadoes this way. I had to plane the underside before it fit. Better that than a sloppy, loose fit.

|

| ditto for the right one |

I got both of these to seat fully and especially at the front. I had to clamp them to close them tight.

|

| sigh..... |

This router works well for getting the slat mortises to the same depth as the dadoes. However, today it would not stay set - the back screw would loosen and the depth of the iron would increase. The solution is to put a nut to help and hold the iron where it is set. The headache is the locking screw is metric. After faffing about I finally figured out it is a 6mm fine thread. I couldn't go to ACE because the truck was in the shop and my wife was off doing her dead people stuff. I'll come back to this in the AM.

|

| it worked |

Used my two small routers to get the dadoes and slat mortises to the same depth. The depth ending up being an 1/8" deeper than I wanted them. Not a big deal but it was an annoying hiccup.

|

| side by side |

The left one is for the grandson(s) and the right is the request. The biggest difference is the size of the shelf. I am going to try my best to make both of the ones I'm making for the grandsons to be the same.

|

| side view |

The end heights are about the same but the width is 2" more on the left one.

|

| hmm...... |

This shape is growing on me. Most of my previous ones I made the tops on the ends parallel to the bottom.

|

| finally understand this |

When I first got this I had a ton of problems setting the angle. Yesterday and today it just fell into place for me. The key for me was to make the lock handle the reference. DUH.

|

| oops |

Made a me-steak here. I should have sawn the angle first and then the cutout for the legs. I was able to 'fix' it. I sawed the angle and sawed the cutout again.

|

| worked |

I had to saw the back half of the cutout again. Rasped and sanded it smooth. No need to go nutso here because it isn't visible.

|

| for the Miller Dowels |

This worked well on two builds. I'll add this step to future ones going forward.

|

| goal met |

Glued and cooking. I might do the Miller dowels after dinner.

|

| Lowes run |

|

| the ends |

As I did with the first grandson's bookshelf, I didn't thickness the ends to 9/16". Instead I labeled the reference face as the inside. The opposite face I just flattened. I didn't attempt to make it parallel to the reference at all. I think it looks good having the ends as the anchors being a wee bit thicker than the other parts.

|

| left side laid out |

If I didn't have to deal with the truck issues today, I might have gotten the dadoes/mortises chopped today. I don't anticipate any hiccups betting it glued and cooking in the AM.

accidental woodworker