Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Be sure to visit the Hand Tool Headlines section - scores of my favorite woodworking blogs in one place.

Norse Woodsmith Blog Feeds

pic frames and cabinet, parts IV & XXVIII........

|

| last night |

Went back to the shop after dinner and played with the front edge support thing. This dry fit looks pretty good, the gap is acceptable. It was hard to tell if there was one or if it was just the dark line between the pine and the 1/2" plywood.

|

| the fix |

Knocked off the square edge at the bottom and planed a slight angle on the front face. It was a balancing act between getting a good glue bond surface and not having a )@%^(Q@%&)&*Q)@_%( gap.

|

| glued and cooking |

Got a good fit and surprisingly very little glue squeeze out.

|

| underneath |

Ensured that I clamped the bottom of the pine to the 1/2" plywood. Counting on this to keep the shelf stiff and straight.

|

| this is complete garbage |

This plywood consists of two extremely thin face veneers with a sponge like single ply between them. This plywood is light as a feather and as stiff as wet pretzel. I sanded the plies so it was smooth so I could lay a pencil against it.

|

| good fit (2nd shelf) |

The left side is square, or this piece of total crap plywood says it is.

|

| right side |

This side was square and it wasn't. I finally zoomed in on the headache, the cabinet side stile was cupped. I saw it clearly when I put the plywood on this side. I planed the stile until the square showed the cup was gone.

|

| hmm..... |

The pine was flush except for a small bump here by my finger. It took a few extra calories before I got it flush. Wandered a wee bit into the face veneer of the plywood too.

|

| first one fitted |

The fit isn't dead nuts perfect but a 100% better fit than the solid wood shelf I first fitted.

|

| 2nd shelf |

This one was a PITA. I had trouble with the hot glue sticking. Finally sorted that hiccup out and got my pattern laid out. I sawed it out allowing a generous margin that I planed down to. Am I out of the loop but does alcohol break down hot melt glue?

|

| the gaps |

I have scraps leftover from making the bead moldings that I can use to fill in the gaps. The left side is wider than the right one. This is going to be tricky because I want to paint the inside of the cabinet without the shelves in place. I am going to try and secure the inserts to the plywood shelves. However I'm not sure that I'll be able to drop the shelves into place after that happens.

|

| 2nd shelf glue and cooking |

I didn't screw up making the pine front edge support thing. It came up an exact clone of the first I did yesterday.

|

| first frame layout |

I forgot to allow for the inside bead molding. The sides, top, and bottom will be less than 1 1/2". The two between the middle pic will be the 1 1/2" I planned for.

|

| 2nd frame layout |

This one has all the same kind of tools. The hand plane in the above 3 doesn't quite fit the grouping but it is the best I can do.

|

| 3rd one |

Not too bad, two of the three blend together. After looking at the three I realized that I have every tool except for the side rabbet plane in the 2nd frame. However, I have a set of left and right side rabbet planes.

|

| grain raising |

On the last frames I made I raised the grain before painting them. That helped a lot with the first coat coverage. A bonus with wetting done the frames was the wood putty smoothed up nicely.

|

| waxed |

I used this as clamping caul. On the first one some glue squeeze out adhered the face veneer to the shelf. That cleaned up easily and it will be painted but with the 2nd one I waxed it and nothing got glued this time.

|

| change of plans |

Rather than cut the shelf supports shorter, I am going to notch out for them.

|

| done |

I like this look. It looks to be a bit more finished with the end of the shelf support buried in the front edge support thing.

|

| why I notched |

I cut this set down to fit behind the front edge support thing. I still have two full length shelf support sets for the shelves.

|

| why |

The cut down shelf support is too short on the front side stile to screw into. As is the screw would be in the groove for the panel.

|

| better |

With the full length support the screw will be back from the front edge of it and go into solid wood on the side stile.

|

| sneak peek |

I don't like the spacing. I am going to position the top shelf the same distance down from the top as the bottom shelf is up from the bottom.

|

| done |

I like this better than the sneak peek but it could be better. Adjustable shelves IMO allow for flexible shelf positions. I got the shelf supports screwed in dry. I will glue/screw them in later. I'm thinking now maybe I should put a board at the back of the shelves to keep that from sagging.

accidental woodworker

Five Mile Lane

I don't need a reason, but happy to have one (to survey a property/job a stone's throw away), to drive down Five Mile Lane to Slapton Ley.

Slapton Ley is a freshwater lake, separated from the sea by a shingle bank. It is a haven for birds in Start Bay, here in Devon.

The house itself was Grade 2 listed and I always warm to a property with lion head gutters.

It needs the usual box sash repairs and repair work to the porch.

After examining the building I had a look in at Stokenham Church. There were a few nice carving details.

And lots of painted panels.

This one of a wolf caught my attention.

Then a drive back along the Ley (oh what a pity), to Slapton, to travel back up Five Mile Lane, and onwards to home.

pic frames and cabinet, parts III and XXVII........

|

| last moldings dry fitted |

I didn't survive this without another hiccup. I cut the miter on the last long one short and I had to whack out another one. Glue and pin nails are in the on deck circle.

|

| 1/4" rabbets |

I am going with butt joints for the rabbets. They will never be seen and Maria covers them with a gray paper like thing.

The blue tape is holding a super glued blow out. One 1/4" rabbet as per Maria's instructions.

|

| 2nd one done |

I used 5/8" pin nails and I had a couple blow out and peek up in the stiles - nothing in the rails though. Nailed punched them below and filled in with wood putty. Paint will hide any evidence of it.

|

| wood putty |

This tub turned to stone on me. I poured a bit of water in it and it softened the putty to where it was spreadable again. I've used it several times since then without seeing any ill effects from that. I filled in all the pin nails and I'll let the putty cook until the AM.

|

| done |

All three frames have the rabbets installed and the nails filled with putty.

|

| went one for two |

These are two extra frames I glued up yesterday, I unclamped them and one was twisted and one laid flat. Out of the 3 extra frames, two were twisted and one wasn't. And one of the twisted frames is iffy - it might work with glass installed and matting etc etc.

|

| paint tomorrow? |

3 extras on the left, and the 3 good ones on the right. I checked all 3 of the good ones and they were ok. I should get them to Maria sometime next week - thurs/fri?

|

| pattern time |

This is what I came up with for fitting the shelves. I cut up some 1 3/4" wide strips of 1/4" plywood and set them in the bottom of the cabinet tight against the sides and back. I used hot melt glue to hold the strips together.

I thought of doing this days ago but I've been putting it off. Getting down on my knees to work on the ground is not easy for me. Getting back up and defying gravity is worse than going down. A concession to me getting older that I have to deal with.

|

| bottom shelf position |

Snug fit and it is self supporting. I will glue and screw the shelf supports to the sides of the cabinet and then glue and screw the shelves into them.

|

| first shelf laid out |

The bottom left corner is square - it has the factory edge. The top was a frog hair off square and the right side was 2 frog hairs off square.

|

| fitting the shelf |

I used the level because it helps with planing. I had to plane two edges to the pencil lines.

|

| happy with the fit |

Snug and self supporting which made me happy. The two shelves will be essential in strengthening the cabinet and preventing racking. I don't like the gap on the sides between the stiles. I'll be filling them in when I install the shelf supports.

|

| sneak peek |

You'll have to rotate these to hoe they will be in the cabinet. Here I'm looking at the extension of the shelf past the end of the shelf support.

|

| hmm...... |

The upcoming front end shelf support isn't as straight forward as it looked. I have to make a rabbet for the support to fit on the shelf and have it extend past the shelf supports 5/8". It was tricky for me to picture it my mind and I was prepared to have a hiccup or two doing it.

|

| fingers crossed |

I think I got it figured out. The first step was to cut the shelf depth (front to back) to 5/8".

|

| got it |

The wide part of the pine is sufficient to mold a profile on it. The thin piece underneath is a wee bit too long but I can cut that to fit. As it is now the shelf support is too long. So I'll have to cut it shorter or the shelf front edge support.

I sawed it a few frog hairs longer than needed. After it has been glued and cooked I'll plane it flush with the sides of the shelf.

|

| teeny gap |

The molding part is proud of the shelf and I'll flush plane it later. There is a frog hair gap between it and the shelf. I wasn't sure where the headache was but I'll deal with it before I glue it up in the AM.

|

| past quitting time |

It has been a while since I got in the zone and time slipped by me. If I hadn't looked at the clock I would have kept on trucking.

|

| need one more |

The bottom shelf pattern won't work for the 2nd shelf. The back right corner has a strong 1/8" gap. The front is snug and self supporting.

|

| this has to go |

I might have to rethink the door stop thingie. I could use the front edge of the shelf to do double duty. Food for thought and I'll deal with that in the AM.

accidental woodworker

26 Trips Out, 26 Trips In; 23 Trips Out…

Recently for the umpteenth time (25th? 30th?) over the past four decades I taught my Introduction to Historic Woodfinishing workshop, this time at Joshua Farnsworth’s Wood and Shop School near Charlottesville. I have already related the transition from teaching at The Barn once my insurance underwriter yanked the plug on liability insurance for students, bringing the “school” component of The Barn on White Run to an end. Joshua graciously invited me to teach at his place, for which I am very much appreciative. I’m teaching a Parquetry workshop in a couple weeks, there are openings.

33

33

The odd thing about teaching workshops at The Barn is that I still have personal liability insurance, the building and its contents are insured as before, but no insurance for students attending classes. The underwriters would never say why that insurance was being canceled, but my agent thought it was because the nearest full-service hospital is almost 90 minutes away. Oddly enough I can still host visitors for one-one-one learning experiences, and in fact I have one of those upcoming as soon as we can work out our scheduling hiccups.

One of the great benefits to hosting all the workshops in my own Barn classroom was that everything I needed was right there. When I teach elsewhere I have to pack up everything for the course. Everything. All the supplies, tools, workpieces, everything. I learned my lesson the first couple times I taught almost forty years ago and sent the students a detailed list of everything they would need. Every class there was a student or two who arrived unprepared, saying “I didn’t think you meant that,” or “I decided to substitute this or that.” In every instance the whole class was delayed repeatedly while I tried to come up with a reasonable substitute, but it never worked out to my satisfaction.

Now I just bring everything necessary for the full experience of my syllabus. Yes, it takes me a week or longer to compile the pile, yes it takes a day to load my truck to overflowing, yes it takes me about four hours to get set up wherever I am teaching. But it yields the learning experience I want to impart.

And the title of this post? It took me 26 trips to move everything from my barn into the truck, then 26 trips from my truck up the stairs into Joshua’s shop. Three days later I had only 23 trips from his shop to my truck as the students consumed the “missing” three tubs worth.

Stay tuned.

Four Shrinkpots and Some Tool Thoughts

FIne joinery saw - ultimate edition

2nd day making pic frames.......

|

| #1 unclamped |

Double, triple checked that this was laid down flat to the bar clamps. Wanted to start with the frame cooking it flat. Out of the clamps, the frame lay flat on the workbench with no rocking. Happy face on, one down and three to go.

|

| didn't make it |

I went 3 for 4. Pic frame #4 didn't cooperate. This one is twisted with the high corner over an 1/8" off the workbench. This is too much to ignore especially so with the glass that is going in here. That glass would be roughly 12" x 24".

|

| 5 1/2 |

This plane performed effortlessly flushing the the corners (freshly sharpened/honed). I did all 3 frames that passed the no twist test in about 5 minutes.

|

| #3 |

The stiles were a few frog hairs proud of the rails. I flushed them because I will be applying moldings to the outside and inside edges of the frames.

|

| 3/16" bead |

On the first of the tool break down pics I applied 3/16" bead molding to the inside edge and 1/4" bead on the outside. Washing, rinsing, and repeating for these 3.

|

| got 12 moldings |

I used some scrap 2" wide pine to make the 3/16" moldings. I was able to get 6 moldings from one board - got 12 total from two.

|

| 1/4" bead |

I could only get 4 moldings from this. On the 3/16" one I got two from the center waste.

|

| sigh |

The square one is the center waste and it is too thin to make a 1/4" bead.

|

| the moldings |

I sawed the moldings out to be 7/8" high. That way the bead will be a wee bit high of the frame.

|

| two frames dry fitted |

Still trying to decide how I will attach the moldings. One way is to glue and clamp them and the other is use glue and pin nails. The pin nails are ahead by a foot.

|

| frame #3 short 1/4" beads |

I had to make two new moldings for the stiles. I had four 1/4" bead moldings left over (from the first tool pic frame) for the short rails. I'll get this one dry fitted in the AM and then get them attached. After that it is paint and bringing them to Maria for her to do her magic.

|

| two new long ones |

I made one boo boo with the first round of moldings - mitered a long one too short. Another one I had to shitcan due to the bead being total crappola. That one looked looked like I had made it with a dull butter knife and a rock. Another headache I had to deal with was on the 1/4" beads I couldn't get two moldings for the rails out of one bead. On the 3/16" beads I could do that. I only made two that I need with no back ups. If need be I can get 3-5 more out the scrap I used to whack out these two.

Had a short day in the shop. I had a PT appointment at 1300. That went well and I learned that my right hip isn't any where as strong as my left one is. I can't lift my right leg upwards with a bent knee. Nor can I cross my right leg over my left one while sitting. My goal is to able to do the right over left thing. Updates in 6 months on the 6 o'clock news.

accidental woodworker

6 more......

|

| hmm...... |

I placed 3 of 9 pics for the next 3 frames to come. The 9 pics are 6" x 9" and this frame here the pics are a few inches smaller. These pics don't allow much for any separation between them.

|

| breaking down the stock |

Confused myself here. I only had to make 3 frames. I had a brain fart and doubled everything up and ended up with 6 frames.

|

| sigh |

Cutting this defect out meant I lost one long stile. I had to break down another board.

|

| the stink started here |

I looked at these two piles and wandered out into la la land. The right pile is the long stiles for 3 frames. The shorter pile on was the rails - 2 from each board. Instead I assumed the left pile was stiles too and I had to make rails for both piles.

|

| 1/2" x 3/8" |

These will be used to create the rabbet on the back of the frame for the matting, pics, and glass.

|

| where I went off the deep end |

Looked at this and thought I had to make rails. Failed to register in the brain bucket what the left pile was for. I made enough rails for 6 frames still believing that I was only making stock for only 3.

|

| using dowels |

The frame went together but I still made a boo boo on it. Not one that demanded flying lessons - my labeling didn't line up. I would have bet a lung I checked and aligned the check marks before drilling. It still went together and that is the important thing.

Dry fit was good. No gaps and the diagonals were less then a 32nd off. The rails and stiles were all proud a couple of frog hairs. That was because the rails and stiles weren't all the same thickness.

|

| labeled and ready to drill |

This is where it finally dawned on me that I had made 6 pic frames instead of the needed 3. I'll make them all and I'll use the best 3 - the other 3 I'll stick in the boneyard.

|

| dry fitted |

It was time to fill the pie hole and go on my post lunch stroll.

|

| glued and cooking |

Got four of them cooking in the PM session. I would have done more but I only have eight 24" bar clamps. I thought of using my new miter clamping things but I didn't want to couple two threaded rods together. The long leg on the frames is 28" which is 4 inches longer then the threaded rods. Besides with dowels I only have to clamp in one direction.

|

| the only one |

Of the 6 frames I did, this is the only one where the labels aligned on all four corners when I drilled the dowel holes. I felt like I drilled this one exactly the same as the other 5 but this one....

|

| been thinking on this |

The bottom right corner is slightly off square. The left corner is square-ish as is the front threshold. I have been thinking of some way to fit the shelf. The solid wood shelf I did doesn't fit. There is a tapered gap because I had to trim the right side. Since I'm going with fixed shelves I what them to be gapless and snug fitting. News and pics on the 11 o'clock news.

accidental woodworker

My Sakura Journalling Sketchbook

Bass Guitar Build Pt 5

Now is the time to prepare the fretboard (compound radius etc.), install the frets and dress them. This isn’t the most exciting stage of the build but of course frets are pretty essential to any fretted instrument!

Moby Dick Book Box

done......

|

| hmm..... |

Still getting strange patterns. From this I would guess that I have a big hollow.

|

| gone |

This is the look off the 8K water stone. Any evidence of the hollow is history. I was able to get a complete shiny bevel on almost every iron I sharpened.

|

| next iron |

This is the next iron after coming off the 8K water stone. Try as I might, I couldn't get the bevel to be completely shiny R to L. I tried for over 30 minutes wearing out my arms running this iron over the stone. I left as is after saying No Mas.

|

| the iron from above |

The plane spit out full width and length RML shavings on the first try. All 3 of the shavings were a consistent thickness too. It would seem that the shiny bevel R to L doesn't mean diddly squat.

|

| wasn't a fluke |

Backed the iron off a wee bit to get a thinner shaving. All three were the same width, length, and thickness - but this time a wee bit fluffy. The plane spit out these shavings effortlessly. No ragged out or crappy shavings on the R and L shavings - where the cloudy parts of the bevel were.

|

| yikes |

I did this - I had knocked over my coffee cup and it had spilled on the plane. I didn't know it when the spill happened. I found this hiccup later. I'll find out in the coming years if this rust will play havoc with this bevel.

|

| this worked well yesterday |

The clear bucket I soaked the water stones in. The red one contained all the sharpening grit. I don't think I'll need the wooden tray now.

|

| 4 1/2 |

RML shavings spit out perfectly on the first set up. This plane has a 55° frog and I use this one for squirrely grain. I had to fiddle with this one a wee bit. The frog was set forward too much. I wasn't expecting that because all I changed was a different iron. After I reset the frog, I got RML shavings on the 3rd attempt.

|

| #4 iron |

This is what I saw when I made 5 strokes on the 1000 grit water stone. I dropped down to the 220 stone and started again. On that stone I got the same look on the bevel R to L.

|

| off the 8K stone |

I started with 220 then 1K, 4K, finishing with 8K. With each grit I switched to the next one only after the bevel look was consistent R to L.

|

| #3 RML shavings |

This plane was not cooperating. It wouldn't initially make a full width and length shaving on the R or L. After playing with it and giving it a ton of free goofy looks I found the hiccup - the chipbreaker screw was too loose. The iron was shifting slightly as I planed this scrap of pine.

|

| almost see through |

This was the thinnest shavings I could make that were full width, length, and thickness. I made thinner, wispier ones but they weren't full width but I did manage to make them full length.

|

| post lunch stroll time |

Finally got all the irons sharpened. I cleaned up this mess after I got back to the barn.

|

| nope |

I thought I was done but I had one more iron to do. I set it aside for the PM session.

|

| it survived |

I was asked how this stone holder was dealing with the wet environment? No headaches noted so far. I put a couple coats of Total Boat penetrating epoxy finish on it. I used 3/4" exterior grade plywood for the base and pine for the stone stop thingies.

|

| honing jig center wheel |

The wheel on the right is a replacement wheel for comparison. The jig's wheel is the same size as it but lacks the shine of the replacement wheel. Regardless of that, both of them feel the same. The jig wheel looks dull and rough but it isn't. It is baby butt smooth, 360.

|

| done |

This tray is heavy. I would guess that it weighs 5-6 pounds easily. No finish for this but I do have some Total Boat epoxy penetrating finish if I decide to finish it.

|

| hmm...... |

Sawed this corner removing the gap due the miters not being equal. I was thinking of doing the same saw cut on the other 3 corners but nixed that. I'll keep this with just this corner sawn.

|

| glass door cabinet |

This is what I plan on adding to the front of the shelves. 3/4" thick pine with a 1/2 x 1/2 rabbet. It will hide the plywood plies and help stiffen the front of the shelf against sagging. It will allow me solid wood to plane a profile too.

|

| shelf positions |

Decided to go with two, fixed shelves. That will give 3 openings that are roughly 15 1/2" high and about the same depth.

|

| got it today |

I have two more of these to make. Those pics are a little bigger than these and I'll make two and bring them to Maria at the same time. I'll wait until I have all three before hanging them in the back hallway walls.

accidental woodworker

Field Trip

Recently my friend B invited me to accompany him to a day in Waynesboro at the Virginia Institue of Blacksmithing for their “open shop” session during which he was going to fabricate a replacement part for his wood stove. It was a most impressive facility and I am browsing the class schedule to attend some myself.

There were more than a half dozen former and current students ranging from young teen, working with his mom on a project, to geezers like me. They were all working on projects doing broaching, hand forging, power hammering, riveting, plasma cutting, welding and a lot more.

two distractions first.......

|

| yikes |

The platform I made to hold my #8 was starting to separate. I had nailed and glued the 1/4" plywood to the back edge of the platform. Sure glad that I noticed this before the platform dumped the #8 on the deck. This was the first distraction to deal with.

|

| distraction #2 |

This is philippine mahogany left over from something. Just enough to make an open box to hold a water stone. Using water stones is incredibly messy and you have to contain it. That is what I hope to accomplish with this.

|

| the plan |

The 1/8" tongue will be my water stopper. I'm hoping that it will swell and keep the mess inside the box. Not sure how it will go because this wood is dense and heavy. No clue as to whether or not water can soak into it.

|

| oops |

One corner miter will be a wee bit shy. Originally I had planned to rabbet the corners but that would have exposed the groove for the spline. So I switched to mitering the corners but came up a wee bit short. The spline groove will still be hidden and this is a shop project.

|

| dry fit check |

The walls are 3/4" high which should be sufficient. The water stone doesn't need to be soaking in water while it is being used.

|

| survived the glue up |

The dry fit went off without any hiccups but with glue applied it was like I suddenly lost my ability to use my thumbs. Finally got it clamped before the glue flashed off. I will let this cook until tomorrow.

|

| surprise |

I forgot that I had this - the red thing. It is a water pond for water stones that I got in the early 1980's from Lee Valley. I didn't need to make the water stone station that I just glued up.

|

| surprise #2 |

Forgot that I had made this water stone holder too. The original water stone holders finally got flying lessons. They were tippy, fiddly, and a PITA to use. This holder worked a bazillion percent then they ever did, even when brand new.

|

| hmm..... |

The bevel on this iron was 30° and I changed it to 25°. The water stone is 220 and it did a good job reducing the angle. In fact I couldn't see/feel much different between it and the 60 grit sandpaper on the runway.

|

| ??? |

There is a nice shiny bevel around the middle with two dull looking stripes at each end. I seem to get this just about every time with my plane irons. I applied more pressure on the outside edges and nada. I had a consistent burr from R to L and a straight edge laid on the bevel showed no light under it. It doesn't seem to effect making shavings. This is the 8000 grit water stone but this stripe effect shows up on the 220, 1000, and 4000 stones too. Just a '...what is this?....

|

| one more to go |

I didn't know that I had 3 extra LN irons. These will fit in the 4 1/2, 5 1/2, and the 51. The one I'm holding I am pretty sure I sharpened on the diamond stones and it wouldn't make a full width shaving. I'm betting on the water stones to fix that. Fingers crossed and I'll find out in the AM.

|

| the herd is getting lonely |

I hadn't expected this to take this long. These four should go quickly because they only need a touch up.

|

| came today |

Twenty five 1/4-20 wing nuts for $13 and I only need 8 for the pic frame clamps. I also ordered 20 black oxide 1/4-20 wing nuts from Blacksmith bolt. I should have them by friday.

|

| hmm..... |

Beefed it up with a piece of 1/2" plywood this time. I glued and screwed that to back edge of the platform (original was glue and brads). The other one lasted for a couple of years and this one should outlast me. I'll put the #8 in it in the AM.

accidental woodworker

maintenance day......

|

| 60 grit |

I have tried in the past to square or remove nicks from the toes of blades with 300 or 600 grit stones. You are there forever so I started using adhesive backed sanding strips. At first I started with 220 and progressed down to 60 grit. From there I go back up to 80, 120, and 180 before finishing on my diamond stones.

I don't like using a grinder mostly because of I'm not good at it. Practiced on a couple of used up irons and the results weren't pretty. So I stay away from that tool. Then there is the issue with drawing the temper out of the iron. All and all it is safer for me to use sandpaper.

My 'runway' is a synthetic threshold I got from Home Depot. This one I only use one side but my second one I use both sides of it. I should set this one up to be dual sided too. I have stops on it but I found out through use (on the 2nd one) that I don't need them.

|

| clean up |

I use a heat gun to remove the sanding strip and paint thinner to scrap the adhesive off the runway. Splash a little paint thinner on it, wait 10 seconds and you get to scrape up a gooey, sticky glob of adhesive.

|

| Lowes run |

Bought a 2x2 and a 2x4 foot 1/2" birch plywood panels. I made up my mind on the shelves and this is what I'm using. 3 fixed shelves or maybe only two. The bottom shelf is going to be hard to see the back of it, especially the very bottom shelf of the cabinet. I might eliminate that one or put in a 1/2" shelf.

|

| LN 51 iron done |

Off the miter saw jig - rough and ugly looking. Took a while due to having to remove a nice sized chip at the toe. Forgot to snap a before/after pic of that.

|

| dead nuts smooth |

Sharp does cure a lot of ills. This is the same molding that the LN 51 chewed up and destroyed. I tried planing it both ways and both the LN 51 smoothed them both dead nuts.

|

| chip |

The bevel and toe of this looked good and I thought it would be easy peasy to knock out. Instead when I made 4-5 strokes on the runway to establish the look of the bevel, it showed a chip almost dead center on the toe.

|

| woodpecker square |

This square is awesome for checking square on chisels and plane irons. Before I got this trying to check it with my 4" adjustable square was frustrating to say the least. The inside faces on this square are 1/2" wide which allow it to register on the edge of a piece of paper with ease.

|

| almost ready to road test |

This chisel didn't take as long to do as the LN 51 iron. I tried to use this chisel before but set it aside because it wouldn't hold an edge. I'm hoping that with the passage of a few years since then my skill at sharpening as been upped a wee bit.

|

| super clean and smooth |

The chisel worked this 45 better than I remember it working. Sliced through it like a hot knife through a tub of cheap oleo. To prove it wasn't a fluke, I did two more of them with the same results. I don't recall this chisel staying this sharp.

|

| 2nd O1 iron |

5 strokes on the runway and I have a thin ribbon right at the toe that ain't cooperating. It took me over 45 minutes to completely remove it. This was the last O1 I had to sharpen. Tomorrow I'll start on the A2 irons.

|

| finally done |

The toe looks fractured and erose but it isn't. That is the burr on the backside. The burr is consistent in size from the R to the L. This is ready for the diamond stones.

|

| for tomorrow |

It was a few minutes past quitting time so this will get done in the AM. This is my spare iron for the LN 51.

|

| my Makita hand planer |

I broke this out because if I didn't do while I was thinking about it, it would stay in its black hole forgotten for who knows how long. This is bigger than what I remember being. The electrical cord is still in decent shape - supple and without any cracks or nicks.

|

| hmm..... |

This I totally don't recall. I thought I had two thick irons with slots in them. This looks exactly like the blades that are in the WEN hand planer. I'll search You Tube to see if there are any tutorials on blade changes/setting.

accidental woodworker

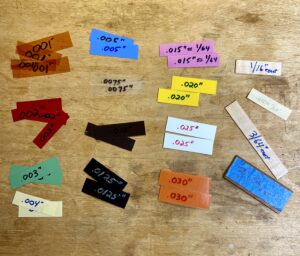

Measure with plastic shim stock

Ladderology 101

On a recent trip to Maryland I needed to address the almost-giant crape myrtle that seems to grow a half-dozen feet a year. It is at that awkward stage, too big to snip from the ground or even a small step ladder, not quite big enough to get from an extension ladder leaning against the house. Using my small extension ladder against the tree trunks is a bit hairy as the ladder rocks back and forth depending on which of my feet is bearing my weight.

Then came a blinding flash of the obvious; what if I create a crook at the top of the ladder so it nestles nicely against the 6-inch trunk, and stays put while I am climbing up or down, or working?

So I pulled out a piece of 1/8″ x 1″ aluminum bar stock from my stash and bent it with just a bench vise and arm power to fit the space above the top rung. 1/8″ x 1″ aluminum is pretty wimpy stuff until you bend it and screw it to a fixed frame, then it gets pretty stout.

Viola! It sits nicely against the trunk, not wobbling back and forth, allowing me to climb, descend and work with my Japanese pruning saw with much greater comfort.

Another win for the blinding flash of the obvious.

glass door cabinet pt XXV..........

At 1238 this PM I officially had adult supervision again. My wife came home after visiting the grandkids in North Carolina. Once I no longer have to babysit Mr Darcy (our male cat) I'll be visiting NC too. As an aside, Mr Darcy did his normal cat routine and treated my wife like she was a stranger. That will learn her for going away without giving him any treats.

|

| the storage part |

I ordered some black oxide 1/4-20 wing nuts from Blacksmith bolt today. McMaster-Carr has brass ones - pkg of 25 for $13 plus S/H. Haven't pulled that trigger yet because Blacksmith bolt had a cheaper price. I have it in the cart so I can indulge myself later.

Made one boo boo with the box. I forgot to center the middle three sided box - it is 1/2" to the left of center.

|

| getting better |

These are Lee Valley clones of Stanley cornering tools. I'm getting better at using them. I'm getting less and less tear out but I still have some. I rounded all 3 edges on the lid moldings and only the top of the bottom molding. No finish for this - yet. But if I change my mind I'll probably slap a few coats of shellac on it.

|

| glazier's points |

These are bigger than I wanted but they are also the smallest ones I could find. Fingers and toes crossed that the paint store has the smaller ones. These will be good for the larger lites due to the thickness of the glass. I think these are too big for the smaller ones though.

|

| hinges |

These are stop hinges and I'm happy with them. I initially thought that they were flimsy but I have used them on several boxes and all of them have withstand the abuse I've heaped on them so far.

|

| hmm..... |

Decided on using a snap catch but I forgot how to do them. It has been a long time since I used this kit.

|

| ta-da |

Figured it out. I eyeballed the snap catch on the box the catches were in. Muscle memory kicked in and I knocked it out easy peasy.

|

| done |

I'm happy with how this turned out. I don't have a warm and fuzzy about the threaded rods but they shouldn't get munged up as is. (fingers crossed)

|

| glass retainers |

Made 6 long ones whereas I only need 4. Started working on the smaller ones for the smaller lites. I need 24 of them.

|

| stockpile |

Made 40 of the smaller ones with one to use as backer when I shoot the miters.

|

| short retainer |

All of the horizontal muntins are the same length. The small vertical muntins are a 1/8" longer than the horizontal ones. I roughed out all of the retainers a wee bit longer than that and I'll fit them individually when the time comes. That will most likely be after I paint the cabinet.

|

| LN side rabbet plane |

Used it to widen the groove so the glass retainers would fit in them.

|

| happy face on |

No light peeking on either leg. Used the 45 clean up jig on the two miters. As an aside, off the miter jig the miters looked ok when I checked them in the lite rabbets.

|

| found it |

I found this molding plane in the boneyard and it is the one I would have used over the one I did. I like this cleaner, simpler look but I would thin the width of the flat above the curved part.

|

| the after pic |

I sawed a 45 on this and it looked like a country lane after a rain storm. This is the look after I cleaned it on the miter jig.

|

| the before pic |

The LN 51 tore this up badly. It looks like slice of swiss cheese now. Happy I was able to clean and smooth it up on the chisel miter jig.

|

| what it is for |

I noticed that when I swing the door shut it flexes. The top and bottom corners move inward. I don't like that because it possibly could crack or break a lite. The first pencil line closest to the front edge is the back side of the door when latched. The 2nd one, furthest from the front edge is where the door stops when latched. I positioned the stop in between the two lines. I secured it with 3 drops of super glue.

|

| done |

I opened and closed the door several times and the stop held secure and the door didn't flex or wobble when it hit the stop. It had a nice secure stop feeling when I shut it. I will put a couple of screws in it later on. For now I want to leave as is and monitor it as I open/close the door.

|

| upcoming maintenance |

The tear out/rough surface I got with the LN 51 was most likely due to it not being sharp (or I was planing against the grain or both). Since I had to sharpen/hone it, I might as well do the other LN planes in the herd. I only have two O1 LN plane irons with the rest of them being A2. A2 sharpens better on water stones so I will break out the waterstones to do the irons. Before that I cleaned up the blades and chipbreakers with mineral spirits. I work mostly in pine and the edges of all of the blades had pine goo on them.

Along with sharpening the blades in the herd I will do the 3 extra LN irons I have at the same time. Added to the plane irons is one 1 1/2" wide firmer chisel. I will attempt to use it to clean the miters on the glass retainers.

|

| my preference |

The O1 LN plane irons are labeled as such with the A2 irons being blank. All of my herd plane irons are A2 and all of their irons are blank - no markings, logos, or writings. I haven't found any LN O1 for sale for years and I check fairly regularly for them. LN stopped making O1 several years ago.

|

| spare LN iron |

I've been pushing this iron up/down the runway for 30 minutes and I've reduced this chip by 80%. I will tackle and finish the remaining 20% in the AM.

Killed the lights and headed topside to chat it up with the wife.

accidental woodworker

glass door cabinet pt XXIV..........

Spent most of the day working on the box for the new picture framing clamps I just bought. I thought I would have gotten that done today but it didn't happen boys and girls. Worked some more on the cabinet and I'm on the fence with the shelves. I think I'm fairly committed to 3 shelves but I'm vacillating about whether to use solid wood or plywood for them. The big concern is solid wood movement vice no movement with plywood. I have the luxury of a few days to wait but I'll have to decide within a couple of days.

|

| 1/4 round molding |

I checked and I can get all 16 short legs out of one molding. I will need two moldings for the 4 long legs of the big lites and one molding for the vertical retainers on the small lites. If I don't screw up I should have almost no waste at all.

|

| I'm getting a headache |

It is looking like the 1/4 round isn't going work. With my spatial abilities swirling around in the toilet trying to orient this in my mind ain't working so well. The miters aren't lining up on this corner. I think I could get it to work if I coped the ends but I haven't ever done coping on such a small molding.

|

| it worked |

The molding is a bit larger (height) than the groove and that allowed me to apply downward pressure to it while I chiseled the miter clean/smooth.

|

| 1/4 round in place |

I don't mind the reveal/margin at the front. What I was concerned with was the molding extending above the muntin bar - it doesn't. It is 3-4 frog hairs below it. However, the miter isn't facing in the direction to pick up the vertical 1/4 round.

|

| happy with this |

I cleaned up both miters in the jig and there is zero light which means the miter is dead nuts on.

|

| the problem |

The moldings aren't uniform which sucks. The left one is fatter than the horizontal one. That hiccup aside, the miters don't line up on either side. I couldn't resolve this hiccup even after giving it my very best goofy looks. Decided to shit can the 1/4 round moldings and go with 1/4" square moldings.

|

| done |

Made a boatload of square moldings. More than enough even if I trip up into a string of oops to deal with. BTW these all came from scraps I was going to shit can.

|

| out of the clamps |

The miters all look decent. There is some glue squeeze out on the toes but they are pretty tight.

|

| L moldings done |

After the square ones were done I made the 1/2" L moldings. I made 6 long ones (27" long) and 4 short end ones.

|

| separated |

I initially wanted to do this on the bandsaw but whacked it out on the tablesaw. It came out a lot cleaner than I expected it to. There are zero fuzzy wuzzies on either the lid of the bottom.

|

| nope |

These are the miters off the jig and although they are ugly looking they are an improvement. I'm still having hiccups sawing the vertical on the miter jigs.

|

| new fence |

I sawed off the original fence on bandsaw and glued on a new one. After the glue has cooked for a couple of hours I will saw new miters and a 90 saw stop.

|

| sigh |

Better but still a degree shy of the exalted 45°. This is why miter shooting jigs were invented for people like me. My shooting jig was off too - it took me 5 plane and checks before Mr Starrett gave his blessing.

|

| yikes |

Noticed this after it had been clamped for several minutes. I had see the toes proud but I canl plane that flush after it has set up. At least this gap will be facing down and won't be readily visible.

|

| dry fitted |

Got a better fit on what is the lid. No gaps on the under side and all the miters are closed up pretty good.

|

| hmm..... |

This was a big surprise. This knurled nut is from the pic frame clamp and I thought it would be metric. After all this is from china but instead of it being a 6mm, it is a 1/4-20 thread. One thing I want to do is get some1/4-20 wings nuts - preferably brass but that will be dependent on the cost.

|

| storage arrangement |

I put 3 'compartments' along the back wall - one at each end and another in the middle. In between them I'll put the 90° corners. The space in front of the 'compartments' will hold the threaded rods.

|

| hmm.... |

This wasn't working. The left end of the bottom one is just plain being ornery. The deeper I planed the profile the more I was ripping out chunks of wood on the left end. The top one I will use on the bottom shelf and the knot will be at the back.

|

| just in case |

Still haven't decide if I'll use fixed shelves or one fixed and two adjustable ones. If I go with the former I'll have the shelf supports ready.

accidental woodworker