Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Be sure to visit the Hand Tool Headlines section - scores of my favorite woodworking blogs in one place.

Norse Woodsmith Blog Feeds

Fun On Labor Day Weekend

Again this year I will be one of the hands-on demonstrators at the 18th Century Trades Fair down in center county. The number of confirmed craftsmen is around 35, working in a magnificent Highland County setting. If you are so inclined it would be a grand day to spend with the family.

Despite having done this twice before I’ve still got a lot to do to get ready.

Stay tuned.

cell phone holder ptII.......

|

| done |

The steam iron box is done. 4 coats of shellac? I am going to leave the stick in the lid to give the shellac a week or so to harden.

|

| 3/8" link belt |

This one fit within the vee of both pulleys. However, it bogs down when ripping boards. It also hesitates when I first turn it on. It takes longer for the saw blade to ramp fully up to speed. Wasn't expecting this at all as I had used a link belt successfully on my last tablesaw.

The original belt even though it has the snot beat out of it and it is chewed up in few spots, it still works. It doesn't bog at all in rip cuts and instantly comes up to full speed when turn on. I'll take a few more links off the belt and see what that does. It should increase the tension which should increase power transmission.

|

| uprights |

Laid out a ten degree angle for the uprights. After I sawed and planed it smooth, I cut a notch in them to hold the shelf.

|

| two mortises |

Took my time and chopped out two mortises for the uprights. Self supporting and no gaps. The uprights aren't shouldered neither.

|

| hmm..... |

There isn't enough lean back on the uprights. I eyeballed the second cut by eye - didn't use a bevel gauge this time.

|

| better |

That should do it for lean back. The first one was too close to zero on vertical.

|

| filled in with epoxy |

I got this epoxy from my wife - don't know why she had bought it. I don't know what type it is but it is slow set. It has a 40 minute open time.

|

| bubble killer |

I stirred a lot of bubbles into this and the heat gun appeared to 'pop' every single one of them.

|

| Yikes |

So glad that this epoxy has a 40 minute open time. I had watched the dark spot at the top right slowly soak up all the epoxy. This was the spot that was soft and spongy too. The second application of epoxy did the trick. When I checked it after my post lunch stroll, it was still proud of the surface. Dead in the water with this now as I'll have to wait until tomorrow to proceed working on it.

|

| sneak peek |

After seeing the shelf where it will call home I'm thinking maybe I should make another one that is wider. I plan on matching the arc from the base onto the shelf. It doesn't appear to my eyeball that it is wide enough for that.

accidental woodworker

cell phone holder.......

The start of today was total overcast (no rain) but it was supposed to be sunny in the PM. So based on that I took a chance and went to Gurney's Sawmill. I had my doubts because on the way out it sprinkled a few times. No rain drops fell but I was a bit apprehensive but I survived. On the return home by the time I was close to the Rhode Island border, the sun was out and the sky was blue.

I was disappointed in the D select pine that got. The same 1x12 I had marked sawing in half a few weeks ago was still available. There were only four 1x12 boards for sale. I only bought three of them and a few 1x10's. I should have called ahead to check but I assumed that stock would be replenished within a week. It would seem that I ass-u-med incorrectly.

|

| mixture |

I bought one 1x12 that was 12 feet long and a second one that was 16 feet long. I also got same length with two 1x10's. Disappointing that I'll have work with thinner width stock. As an aside the 1x12's were 11 1/4" wide and the 1x10's were 9 3/16". Why fart around like this and just sell 1x1's as 1x12s?

|

| 1x10s |

The 1x10's were mostly clear, a lot clearer than the 1x12s. The grader for the 1x12 stock should go back to school and learn how to measure diameters. D select allows for 1/2" diameter knots but I got one board with a 2" diameter one. But there wasn't much room to quibble due to what was available.

|

| still on the fence |

I am now leaning in the direction of turning this into holding a frame. I think that is a better use for it. I can make the cellphone holder with a much smaller base and differently styled uprights. Laying out a large arc on the front edge.

|

| base roughed out |

I have to mortise for the uprights next. Once that is done I will make a chamfer on the front and the two sides. Not sure if I'll continue it on to the back edge but.....

|

| hmm..... |

I was going to leave this as is but I changed my mind. The defect is a little loose and spongy in spots. I am going to fill this in with clear epoxy to consolidate it and keep it intact.

This is all I got done for today. My oldest sister came up for a visit and landed today in Norwich Conn. Spent time with her on the phone and we're going to do lunch on tuesday or wednesday. Excited about having her all to myself for lunch - it has been a bazillion years since we have filled the pie holes together.

accidental woodworker

Masking Tape & Superglue

Bottom rail. In the flow.

On with the bottom rail. Chalked out first, with charcoal to show where the joints will be.

In with v-gouge.

Giving us this.

And grounded.

A few adjustments to make, but you get the idea.

The New Peter Galbert Workshop

which one is it?........

Still applying the finish to the tool and steam iron boxes. Not done with either one yet. I had a physical therapy appointment and that ate up the entire PM session. My left leg is weak and I don't have the ability to lift up my right leg up while sitting. The PT tech spent over an hour going over some exercises for me to do at home along with 10 pound ankle weights. I have a follow up in 4 weeks and check my progress.

|

| hmm..... |

When the internet went out last week I had to surf with my cell phone. It was awkward and a PITA to hold it while watching/listening to it. I thought of making this stand to hold it if and when that need may arise again.

This is the 2nd concept for it. The first one consisted of only one upright and I like the look of two. It makes it look sturdier and stronger with twin uprights. There is more shaping etc etc to come but this gives a starting point for it.

While I was playing around with this I came up with another use for it. I could use it to hold a picture frame. I like the 2nd use more than the intended purpose.

|

| 2nd base choice |

I was thinking of making a thinner width with a slight arc on the front edge. This scrap of cherry is too thin for that but it would work for leaving it as is. And I have two more uprights to left front of it.

|

| the winner |

I like the defects in this piece of cherry for the base. I still have to play with the placement of the uprights to maximize the defects. So far placing the uprights behind it is at the head of the line.

|

| shelf |

The uprights are roughly 3/8" thick and the shelf is about 5/16". Working on how to position the shelf into the uprights. Put it in straight and angle the bottom of the uprights? Or angled both the bottom of the uprights and the shelf into the uprights. The uprights will have angled front faces so that will have to be taken into account too for placing the shelf across the two uprights.

I'll start on that in the AM. I am thinking that I will make at least two of them.

accidental woodworker

A Simple Tray Quickly Made

a no title post....

Slow day in the shop - slapping shellac on the tool and iron boxes. Made a lot of trips up and down to shop but I didn't complete either one. Maybe tomorrow. Don't know what is next in the queue. I thought about it but nada. I'm running out of holes to stick the things I make into. Spent a lot time catching up on my reading.

|

| needed more shellac |

I had enough Everclear to mix up a new batch of shellac. I buy empty quart cans and I usually mix up 2 cups but not today. I should have enough (fingers crossed) to do the two.

|

| two more to go |

I got four coats on the bottom and one on everything else. I might be done with this by tomorrow if I go back to the shop after dinner.

|

| not as quick |

I initially was going to leave all the layout lines in pencil but I nixed that. Used alcohol and 120 grit to erase them. Doing the bottom of the lid and the bottom of the toolbox along with the ends first. This won't done today and maybe not even tomorrow.

accidental woodworker

Latest Gabfest (Definitely *not* Woodworking)

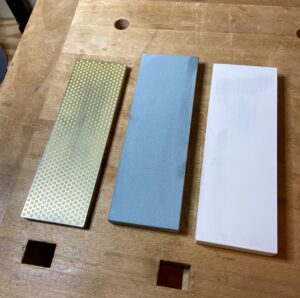

Sharpening logic

Toshio Odate toolbox is done!!!!

The toolbox build didn't go smoothly even though the finish line was in view. All the woodworking is done and I'm thinking of a finish for it. Toying with the idea of painting it? However, that is one finish I haven't seen on line with any japanese toolbox. Another idea is BriWax. I used it on a couple of boxes a few years ago and they still looked good when I recently checked them. Or I could default to my favorite - shellac.

|

| comparison diagonal |

Before I settled on which one to use, I needed to make a 2nd one.

|

| not as wide |

This diagonal isn't as wide as the first one but it is wide enough to compare the two.

|

| hmm..... |

This kills it for me. I don't like the toe of the diagonal extending past the side. I am sticking with the first one.

|

| sigh |

I am not going postal over this but I am upset with why I don't know how I did it. I had four of these saw cuts on two battens and 3 were good and this one is toast.

|

| sliding locking batten |

Leaving this one long. I have found that a little extra length makes it easier to remove it.

|

| got lucky |

Replacing the batten and it is the single one. I don't have to plane a compound angle.

|

| link belt |

The link belt is 5 1/2 ft long which is more than enough for what I need.

|

| not working 100% |

Made a me-steak with this belt. It is a 1/2" wide and the pulleys are 3/8" wide. The saw made a cut but it was bogging donw and actually stalled on me. I ordered a 3/8" wide one from Amazon and I'll have it saturday. This 1/2" link belt will be used on the bandsaw when I finally get around to swapping out the motors.

|

| flipped it |

The marks came from the belt being flipped. I turned it inside out so the little fingers faced downward into the pulley. What a difference that made. It sounded better and stronger and the saw cut and didn't bog or stall. It felt stronger and lest resistant rip sawing a couple of scraps. Just pine and I don't know how well it will perform with a hardwood yet.

|

| smoother |

The edge is not uneven and rough. The wood also seemed to more easily advance through the saw blade. The bonus is the finish on this edge is like night and day to what I have been getting on rip cuts. I wouldn't hesitate to edge glue two boards with this cut. This is also the replacement batten.

|

| transferring screw holes |

Made a boo boo here that I glad no one was here to see. The screw holes didn't extend all the way through. I didn't catch that tidbit on the first go around trying to transfer the hole pattern on the new batten.

|

| done |

I don't know for sure but I think I aligned the new and old screw holes with this replacement batten.

|

| got it right |

I sawed the batten about a 16th longer on each end. Flushed it the blockplane.

|

| glamour pic #1 |

The interior dimensions are 8 1/4" high, 14" wide, and 27 1/2" long. That is a lot of real estate for tools. No sliding till but that is subject to change with whim or boredom.

|

| glamour pic #2 |

I think the lid and especially the built in handles make this toolbox special.

|

| tapered gap |

This is from a supposedly no mortise hinge. This gap causes my OCD to go into overdrive.

|

| made it better |

I fiddled and faddled with making the notch for the hinges for a bazillion years. I would chisel a wee bit and check the fit/gap. I got the hinges flush with the notches but the gap is still a bit tapered. Cut my losses and accepted it as is.

|

| it is a locking catch |

I almost made a road trip to ACE to buy one of these. Saved gas and time by checking my bins and finding this one and 2 others.

|

| for the iron |

1/4" plywood for the iron to sit in. I used the cardboard bottom as the pattern for making this. I sawed it in half to give the iron some wiggle room.

|

| done |

The box is easy to pick up and put away. Here I had convinced myself that this didn't need a finish. After all it is just a shop box.

|

| hmm...... |

The lid wouldn't fit both ways. This end had a slight hump in the middle and it wouldn't slide under one of the battens. After 3 swipes and checks the lid would go on either way.

|

| changed my mind |

Decided to slap on 3 coats of shellac. Before I did that I put wood putty on this end of box which had a couple of teeny gaps. I'll sand and do the shellac tomorrow.

accidental woodworker