Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Norse Woodsmith Blog Feeds

Tomobe – Ne-tsugi

….continuing on from round one of jacking up the house…. …what followed was more demo to open up the walls for some ne-tsugi (post repair using slicing joints) as well as some more foundation work. Demo was also necessary because the earthen plaster walls had separated internally as a result of the sill beam rotting… Read More »Tomobe – Ne-tsugi

The post Tomobe – Ne-tsugi appeared first on Big Sand Woodworking.

Make these bench dogs

World’s Longest Yard Sale 2025

I went on the World’s Longest Yard Sale again this year. We traveled five days traveling from Russel Springs, Ky to Eaton, Ohio, at the I -70 line. It seems harder and harder to find tools. Mainly because the same vendors have the same tools I picked through the previous year. Nevertheless this is what I got.

A couple of Milers Falls planes. These are getting pricier every year as more people realize how well they work.

A bunch of Stanley bench planes and one Craftsman No 5C for $5.00. I’ll buy the parts planes if the price is right as I usually have the correct part to make it complete.

Two Stanley No 48 tongue and groove planes. One is missing a blade, but they’re relatively easy to make. The other has a user made wooden fence that is too narrow to work.

I bought this lot for $20.00. The guy didn’t know what the sun plane body was. I believe the screw handle is from a mitre clamp.

An ivory slide rule and a 2 ft caliper rule I have never seen before. Plus, there are a few odds and ends.

I found the Holy Grail of paste wax. A full can of SC Johnson paste wax for a $1.00. I hit the lottery. lol.

I only spent about $250.00 for everything, but my wife, Anita, made out well. She bought a whole lot more and spent a whole lot more money than me. You can check out her Instagram page at mybuckeyehome to see what she bought.

picture frame last part.........(maybe)

|

| old tablesaw V belt |

This is the easiest way to figure out the belt needed. The other involves measuring the pulley diameters and the distance between them. According to the roll tape the length of the belt I need is 44 inches.

|

| face side |

The gray scotch pad is so different vice sandpaper. It leaves little sanding dust but the surface is smooth to the touch. More importantly the gray pad doesn't sand away leaving bare wood. The plan is/was to get 3 coats of shellac on the front. I want to bring this to Maria on tuesday.

|

| almost ready |

Cleaned up the frame with a damp rag. Just had to wait for it to dry before shellac.

|

| got lucky |

I was on my way to the Auto parts store when I thought of this. I had bought this belt for the bandsaw but I didn't use it. The on center spacing of the pulleys on the table saw and the bandsaw matched. Tried it, it fit, and I made several test cuts with no hiccups. Saved me a road trip and a few $$$.

|

| new side project |

I need a box to keep my peeper helper in. It is a PITA to take my eye glasses out of their soft holder. With this box they are protected but way easier to take out and put away.

|

| glass door cabinet |

I haven't forgotten about this. I've been thinking about how to do the grooves for the panel inserts. I still haven't decided on how to do them. The current leader is using a 6mm router bit because there isn't a plywood imperial 1/4" router bit. The router bit headache is finding a 6mm router bit that comes with an imperial 1/4" or 1/2" shank. I don't have any metric collets.

|

| sigh |

I had laid the frame face down on the workbench and when I put it on the shitcan to start shellac I saw 4 holidays on the bead moldings. Wasn't expecting that and it threw a monkey wrench in applying the shellac. I had to touch up the holidays and I got the first coat of shellac on after I got home from my post lunch stroll.

|

| box is done |

These aren't the glasses that will call this home but they work to check out the specifics. I wasn't sure if I had made the height too high but it looks and works ok as is. I also waxed the entire project with the LAP wax.

|

| 3 out of 7 |

Maria told me that some of the frames had stuck together and it left a few holidays. I touched the 3 frames up and I'll shellac them when I do the big frame.

|

| fingers crossed |

Just realized that I had painted over shellac and I'll be covering the paint with shellac again - effectively a sandwich. Thinking ahead I hope I don't end up with the touch up spots blinking like a neon sign at night.

accidental woodworker

picture frame penultimate.......

Hopefully this isn't going to bite me on the arse predicting this. Got the picture frame painted, two coats, and it is ready for a couple of coats of shellac. Done. Fingers crossed that tomorrow in the AM I'll be doing that.

|

| done |

Happy with the two coat coverage on the back. Consistent everywhere I looked. No bare wood peeking out through the black. Time to wash, rinse, and repeat on the opposite face.

|

| first coat |

If I was in a hurry I could probably get away with one coat. This is the best coverage I have gotten with this paint. I also used a scotch brite pad (gray) to sand between coats on the back. Much better finish with the gray pad. With 320 grit sandpaper (what I was using) it was too coarse and it would sand down to bare wood even with moderate sanding pressure. The gray pad is definitely the thing to use between coats.

|

| LAP wax |

Visually there isn't a lot of shine. I waxed the right side of the cherry and left the left side bare wood for comparison. The dark wood I waxed it all - only thought of the half and half trick after doing it.

|

| the opposite side |

I can see a definite difference on this side. Still doesn't shine like shellac but I like how this looks.

|

| buffed out |

I can see a difference on the cherry. The matte, satin look isn't too bad. The dark wood doesn't have the same look as the cherry though. This could be the look of bare wood if you hadn't seen a comparison.

|

| hmm...... |

Don't need them but I made a couple more bead moldings. I'll stick them in the boneyard for a future use.

|

| an hour later |

I can feel a difference in a finger tip touch between the bare and waxed parts. The waxed parts definitely feel smoother. The same goes for the dark wood. I'm a bit apprehensive about waxing an entire project but in order to make a call on the LAP wax that will have to happen. I'm not a fan of a matte finish but I'm open to see how it looks on a hardwood project. I don't see any value in waxing a pine one.

|

| fingers and toes crossed |

I am maybe a wee bit too confident that I won't have to done a 3rd coat. I'll double triple check this after dinner when it is dry. As it is now I am liking the coverage very much.

|

| hmm..... |

Rather then tossing these scraps of pine I am making 6 bead moldings.

|

| six 3/16" bead moldings |

I can get 3 more bead moldings from the center off cuts. It is looking like two 3/16" and one 1/4" bead moldings with them.

|

| happy face with a wide grin |

All the bead moldings I made in the past few days sailed through my bandsaw. A huge difference in the old 1/2 HP motor and the new 3/4 HP one. The taper hiccup in the moldings I made was mostly non existent. There was zero hesitation pushing the stock through the blade. The sawing action was smooth and easy.

I found a John Heisz You Tube video on a bandsaw sharpening jig that I'm thinking of making. However, I'm a bit confused on what to sharpen. I thought that I would sharpen the inside downward curve of the teeth. But every thing I've seen on sharpening it is the top outside face of each tooth that gets sharpened. Still researching this so I can wrap the brain bucket around the science of it.

accidental woodworker

Latest Gabfest (NOT woodworking)

My friend of 35 years, broadcaster Brian Wilson, just posted our latest conversation over at his Brian Wilson Writes Substack. Feel free to find and give it a listen unless you dislike pungent (but not vulgar) commentary on the current state of affairs, with topics ranging from Self Irrigating Planters in the garden to “Just War Theory” in the world at large and many points in between.

Building Peter Follansbee’s Book Stand (in Exotics)

Last Christmas I was given a few pieces of exotic wood, which have been sitting in my shop since then, waiting for me to make a special little project with them. After doing a lot of work with pine this summer, I was in the mood to make a smaller project for myself, ideally using these special pieces of wood. (I’ve learned that the best time to use that special material I’ve been saving is now.) I had one 24″ piece of goncalo alves and a couple 18″ pieces of purpleheart, all about 4″ wide. After doing some sketching, I confirmed that I could use this wood to make a nice book stand, which I would model on a book stand that Peter Follansbee made.

You can see Follansbee’s version here. It’s a lovely piece, with his characteristic 17th century carving. His blog post gives you excellent directions if you want to make a similar one yourself–provided you have a lathe. I don’t intend to repeat Follansbee’s instructions, but I do want to supplement them–should you decide you want to make something similar but don’t own a lathe.

This is my own version:

The most obvious difference between my book stand and Follansbee’s is the choice of wood and my lack of carved decorations. I admire carved work very much, but it’s not the kind of thing I like to live with. The dimensions of my stand are also different (the reason for which you will see at the end). Mine is 18″ high, and the shelf is 18″ wide, whereas I think Follansbee’s is about an inch shorter. And the dimensions are different. His is more or less square, while mine is oblong. Working with short stock, I could make the rails only so long, which is fine. The lesson here is that this is a very adaptable design. The exact dimensions are not crucial to its function.

I especially like the ratchet in the back, which allows the stand to sit more upright or more laid back, depending on your preference (and perhaps the weight of the book on display). I had never built any mechanism like this, so I was eager to try.

When I showed the finished project to a friend, who is also a woodworker, he asked if I worked to any kind of plan. It occurred to me that others might also like to see the plans I use for my projects, too.

“Plans.”

The reason I seldom show my plans is that they are truly minimal. I write down only the most critical dimensions of the piece. I keep most of the design elements in my head during the building process–especially for one-day projects like this one. Decisions that can be made on the fly (like the exact radius of a curve) are not written down at all. As you can see, the finished product differs from the plans in several details, such as the number of teeth in the ratchet and the addition of a curve on the top rail.

I began, as always, by dimensioning my stock. I didn’t feel like running out to the garage and unburying the bandsaw and planer, so I just did it all by hand. All my stock was 3/4″ thick to begin with, but I reduced the thickness of the shelf down to about 5/8″, just to save on a bit of weight. Purpleheart is heavy, and I don’t want this book stand to be front-heavy! Planing across the grain with a jack plane brought down the thickness pretty quickly, though even with a sharp blade it gave me quite a workout.

Follansbee’s blog post does an excellent job explaining how the shelf is tenoned into the stiles, so I won’t go into detail about that here. But you can see from the picture below how the tenons are shaped. I also bored some peg holes (3/8″, I think), though I did that after everything was dry-fit and I could set a book on the stand to figure out where the holes needed to go in order to hold the book open. I decided to bore two sets of holes, one pair for a smaller book and the other pair for a bigger book.

Next I selected the nicest part of the goncalo alves board for the top rail. The grain had a natural curve to it, so I decided to shape the top into an arc following the grain direction. I penciled in the arc freehand, roughed it out with a coping saw, and fared the curve with a spokeshave. Next I cut the tenons on each end. they’re about 3/4″ deep with a haunch on the top.

I realized I should have cut the tenons first and shaped the curve afterward, as it’s difficult to hold the workpiece on a bench hook with the top all curved. I ended up picking one of the offcuts out of the trash and using that as a shim to help me hold the board in place. It worked surprisingly well. Lesson learned: don’t take out the trash until the project is finished.

With the tenons cut, I laid out the mortises and chopped them with a mortise chisel. I also bored the 1/2″ round holes for the pieces that will rotate for the ratchet.

My auger bits are optimized for soft woods, not for dense hardwoods like purpleheart. When I need to bore a hole in a very hard wood, I typically drill a pilot hole for the lead screw to follow. It really helps.

I cut curves on the top of each stile, which I think is a nice complement to the curved top rail.

I used my glue bottle as a template to trace out the curve on the top of each stile. (I told you I do a lot of the design work impromptu!) After cutting off most of the waste with my coping saw, I again refined the curves with a spokeshave. Clamping them together and shaving them down like this ensures that the curves are identical.

Making the rotating rails for the ratchet was probably the most fun part of the project. The rack and the blade are each tenoned into a rail 3/4″ square. I chopped a through mortise in each one and cut a tenon on the end of the rack and the blade (not pictured). Follansbee’s pieces are turned on a lathe, but I don’t have a lathe. I do, however, know how to make a round shape with flat tools.

Here’s how it’s done.

First, find the center of each end by using a ruler to draw lines corner to corner. The intersection is the center–or as close to the center as you need to get for this operation.

Next, use a drill bit of the same size as your mortise to drill an extremely shallow hole in the end of the workpiece. It’s best to use a bit with a center screw or spur, like an auger bit or a Forstner bit. I happened to use a Forstner bit in my electric drill, which is the only powered tool I used for this project. Now you have the finished width of the tenon marked clearly on the end.

Now determine the finished depth of the tenon, and measure that in from the end.

Mark the line all the way around the workpiece with a knife, and make a shallow saw cut on each of the four faces. You can measure the approximate depth of the tenon shoulder and saw to that line, or you can just eyeball it. Even if you go a smidge deep, you won’t compromise the strength of the tenon.

Now, with the workpiece held upright in the vise, split off some of the waste, going as close to the finished depth as you dare. (This is where it really helps to have chosen stock with dead-straight grain on each end.) You can deepen each saw cut as necessary in order to allow you to split off even more waste.

Because this tenon needs to rotate freely in the hole, it’s okay if you chisel over your line in a couple places. The more you take off with your chisel, the less time the next step is going to take.

Once you’ve gotten as close to your line with your chisel as you dare, use a file to remove each corner, and remove each corner again, until the tenon is roughly round. It helps to use a file with a “safe” edge (also called a pillar file) so you don’t cut into the shoulder by mistake. You could also use coarse sandpaper wrapped around a slim bit of scrap.

Test your fit in the mortise regularly. When it fits well but turns easily, you’re done–no matter what the tenon looks like. This method seems slow, but once you get the hang of it, it’s really quite quick.

I also decided to chamfer the corners of each piece with a spoekshave, which I think provides a nice transition from the square mortise to the rotating end of each piece.

With the whole assembly dry-fit together, I determined how the two pieces of the ratchet would meet. First I tapered the blade with a drawknife and spokeshave to just under 1/4″ at the end. I also narrowed the width of the blade at the business end just a little bit, so any misalignment between the two pieces wouldn’t be obvious to the eye.

With the book stand set at the steepest angle I could imaging wanting it, I marked the location of the first ratchet tooth. The rest are spaced 3/4″ apart.

I just cut them out freehand with a back saw, though I suppose I could have marked out each tooth first. My one suggestion is that you not make the top of each tooth sharp. There’s no need for that. The teeth will be more durable if each one has a bit of a flat left on top.

After removing as many of my layout marks as I could find and breaking the sharp edges with a spokeshave, I glued up the whole assembly. There are only six joints that need glue. Don’t glue the round ones!

While I waited for the glue to dry, I shaped the pegs from a couple scraps. They are about 3″ or 4″ long. I don’t know–I didn’t measure them. After planing them square with a slight taper, I took off the corners with a spokeshave and kept working at them until they fit just snugly into the holes.

I gave the whole thing a couple coats of my home-brew Danish oil, which is just equal parts raw linseed oil, mineral spirits, and polyurethane.

It’s very easy to use. Flood the surface with the oil. Wait 5-10 minutes, and apply a second coat. Wait another 10-15 minutes and rub it down with a clean cloth, removing any excess oil. Let it dry about 24 hours, though the finish won’t be fully cured for another week or so. Still, it’s about as foolproof as a finish can get. The finish gives just enough protection that the wood is easy to clean, but it also lets the grain come through, so the surface still feels like wood and not like plastic. It’s also very easy to renew if necessary.

As the finish dried, I kept rotating the ratchet mechanism, as I didn’t want the finish to freeze the round tenons in place.

The book stand will live in my office at work, where I’ll use it to display some of my more interesting books, like this English translation of Dante’s Inferno illustrated with woodcuts by Gustav Doré.

I like the fact that the book stand is tall enough that even a large book doesn’t completely obscure the tops of the rail and stiles. It would be a pity to use such nice wood only to have it always hidden behind a book.

I do, however, own one book that will hide nearly the whole stand, and I don’t mind that so much. In fact, I built the stand with this particular book in mind.

It’s my Compact Oxford English Dictionary, which my wife and I got at a secondhand shop for $15 quite a few years ago.

The full Oxford English Dictionary is by far the most comprehensive and authoritative dictionary of the English language. While it is now used mainly online, in print it runs a full 20 volumes. But the single-volume Compact edition is something of a technological marvel. Each folio-sized page contains nine regular pages in nearly microscopic print, and it must be read with a magnifying glass. (My copy, sadly, is missing the magnifying glass that is normally provided with the book.) Because I have full access to the online version through my university, I don’t often have occasion to consult my print edition.

But the volume is too interesting to just let it sit there in its box, so from time to time I’ll be displaying it on my new book stand.

picture frame pt II.......

|

| that's a big hole |

The epoxy had set up overnight. It is flush and it is hard. It is looking like this going to last - fingers still crossed due to it being a pitch pocket repair. I'll have to wait for paint to see if the outline pops under it.

|

| planing jig |

This didn't work. I had superglued the stop and on the first planing run it popped off. I nailed on the next one and that one lasted for all 8 pieces. I just had to plane and smooth the bandsawn face.

|

| last inside one |

I fitted the two short legs first and then the two long ones. No hiccups with the inside ones.

|

| last outside one |

This is the dry fit. I glued and nail the two short legs and one long leg first. Then I will plane and trim the last leg to fit. At this point that was the grand plan.

|

| perfect |

The last leg is a wee bit too long which means I can sneak up on a perfect fit.

|

| sign |

I was not expecting this at all. I only took two swipes and I thought that was mostly to square/clean up the miter at this end. Turns out that something was amiss. I must have checked the dry fit incorrectly somehow.

|

| new bead molding |

This is the 2nd replacement bead molding I made. The original one was short as was the first replacement one. Forgot to snap evidence of that me-steak. Found another scrap of pine to make a 3rd one.

|

| why not |

With how my track record was going I made two bead moldings. Spoiler alert - I didn't need the extra.

|

| done |

I like the look of the two different sizes of the bead molding. I like how my eye goes from the fat 1/4" outside bead to the thinner 3/16" inside one. Kind of draws your eye from the outside to the inside.

|

| set and filled |

While the putty set up I went on my post lunch stroll.

|

| grain raising |

Raised the grain with water because I have had coverage problems with this paint in past applications. The paint I'm using (IMO) doesn't cover well on pine but it does do a better job with raising the grain first.

|

| hmm...... |

I wasn't terribly impressed with using the LAP wax. But I was not expecting eye popping results. I do like that this wax doesn't seem to have an odor and it was easy to apply and buff with the woopie towel. I have a couple pieces of cherry that I will try it on next.

|

| first coat |

I spent a lot of time applying the first coat. I double triple checked it 3 times to ensure that I didn't leave any holidays (spots with no paint). I always paint the back first to gauge how well the paint coverage is. I was happy with how this looked. There weren't any faded areas and the coverage looked consistent. I'll get the 2nd coat on in the AM.

accidental woodworker

Drawing and Seeing

Greenhouse Update – Mrs. Barn’s SIPs

Things have been popping in the orbit of Shangri-la, what with summer gardening (soon to be complimented with winter gardening), visiting the grandsons (and their parents), preparing for the upcoming woodfinishing workshop and historic trades fair, and a multitude of other stuff disrupting my writing and blogging routines.

The greenhouse is currently the home for a series of Self Irrigating Planters Mrs. Barn asked me to create for her. We built five different versions and in keeping with her background as a plant scientist she was conducting a standardized experiment to determine which version is the one to go with in the future. We plan to use SIPs almost exclusively inside the greenhouse so her efforts are well worth it.

These images are from a month ago, so the plants are all bigger now and burgeoning with tomatoes or eggplants.

In addition to the greenhouse experiments she’s been harvesting the seeming bushels of green beans we love so much. Nothing quite like fresh green beans, and her dilled beans are the best.

The asparagus season is long in the rearview mirror but was savored intensely in its time. The asparagus plants are now full-blown bushes about ten feet tall. Mrs. Barn sez this is one of the keys to keeping an asparagus bed thriving. She must be right, ours is many years old.

As for all the other activities, stay tuned.

picture frame......

|

| sigh |

Three coats of shellac and it isn't blending in. The shellac isn't the problem, the area I shaved is blinking like a neon sign at midnight. I'm leaving it as is, I don't think either grandson will notice it. I also checked with the boy's mother and she told me that they both needed a pencil box for school.

|

| going vertical |

This is what the new picture frame is for. I looked at these horizontally and I thought the over all length was too long at over 31". With them placed vertical the OD is about 24".

|

| this sucks pond scum |

The belt separated twice on me during use. I had noticed that the blade was bogging again and I had to push stock through it a lot slower - this turned into toast. I'm going to have to find a replacement belt somewhere.

|

| quarter sawn |

I got two pieces of stock 2" wide that were dead on quarter sawn. This should be perfect for a picture frame.

|

| it fits |

There will be a 1 1/2" border on the outside edges and in between each of the pics.

|

| oops |

Got this one wrong. I doweled the frame together and I missed aligning the jig somehow with my X marks. I don't know what I did wrong but the fix is easy enough.

|

| the fix |

Glue in dowels and saw them flush.

|

| drilled it right this time |

I was about a 1/2 of a dowel diameter off to the right.

|

| dead nuts square |

I was very happy with how flush the corners turned out. They weren't dead nuts perfect but, wow they were awfully close.

|

| came this close..... |

Besides the one corner I screwed up I had to scramble to get this glued up. It was like trying to figure out a Rubik Cube. The three other corners had some screwy drilling and I had to figure which way the corners went together. It took me four frantic tries before I got that.

|

| faux rabbets |

These thin pieces of stock (3/8x3/4) will form the rabbet for the glass, mat, backing, and the pics which is about 3/8".

|

| 1/4" |

This is all Maria told me she wants/needs for what she does.

|

| done |

Glued and nailed. After it has set up I'll plane a small chamfer on the outside edge of the rabbet frame.

|

| oops |

Pitch pocket that I had seen and was going to put on the back of the frame. Obviously that didn't happen.

|

| set the nails |

Filled them in with putty. Not necessary but I did it anyways.

|

| deep hole |

As far as I know and from experience, nothing sticks to pine pitch. I used picks, carving chisels, and chip knife to dig out the pitch and out to clean, pitch free wood.

|

| epoxy |

It took almost 5ml of epoxy to fill in the hole. I didn't go nutso on the bottom but the top 1/8" is all clean wood. I cleaned out the hole first with paint thinner and then filled it in.

|

| 1/4" bead |

I wanted to plane a chamfer on the inside and outside edges of the frame. I can do that on the inside but not the outside. The dowels on the outside, closest to the outside edge, could become exposed by the chamfer. So I'm putting a bead on the outside and inside edges.

|

| like butter |

Decided to do a bead on the inside too but 3/16" instead of 1/4". The smaller bead on the inside shouldn't distract as much as a bigger bead would.

|

| the difference |

The smaller one looks like 1/2 of what its bigger sibling is. I think I made the right choice going with a smaller bead for the inside. I'll get the beads cleaned up and installed tomorrow.

|

| trying a new finish |

Lost Art Press had this wax kit in a recent posting and I bought one. Although I am still not sold on wax finishes, I'm willing to give them a try. News, pics, and film on an upcoming 11 o'clock news.

accidental woodworker

Exeter Box

Peter Follansbee is going to be making this box soon. I thought I might beat him to it, but he's much faster at this stuff. Plus the board I need for the top is still a log,

I went to take the photos back in March, and meant to send them to him then, but time slipped away. Anyway, he's got a whole load of pictures winging their way across the Atlantic as I write. Happy carving Peter. I think he's using white oak. When I make it, it will be from this English oak, that rolled in recently.

The box is lovely Exeter strapwork. Our favourite.

At once simple, but complex.

A shooting board for Shooting Edges

I made a new shooting boards for primarily for shooting edges of boards. There ‘s no specific length, they can be as long or as short as your work dictates. I go over some important on how to make it and how it’s supposed to be used.

glass door cabinet pt I.......

|

| a few ideas |

I've been thinking about how to make this cabinet. I don't have any plans, just a pic of the original banging around in the brain bucket. I've been thinking about this for a few days and I'm starting with the sides and back first. These aren't carved in stone so they might change here and there as I progress but I like this so far.

Still mulling over how to attach the top and bottom. Dovetails are out so that leaves a rabbet joint, biscuits, dowels, or simply nailing the top and bottom on. As for the last one I can see doing that for the bottom but for the top it won't look good. Plenty of time to sort that out.

|

| too snug |

The lids fit and I can remove and insert them ok but I am not sure that young kids have the finger strength to do that. Let alone have the patience to attempt doing it. Time to shave the ends with the LN 601/2.

|

| done |

Took a few plane and check before the fit was sufficiently loose. I don't think the grandsons will have any problems opening/closing these now.

|

| too loose |

This is the famous big box store 1/4" plywood (always less than a 1/4") that is too loose in a 1/4" groove. It is not terribly sloppy loose but it also isn't self supporting. I plowed this groove with an iron I had made for me that is undersized. In a 1/4" groove (true 1/4" wide) this plywood is a sloppy fit.

|

| 6mm plywood |

The groove is a true 1/4" wide and the 6mm doesn't fit. I can thump on it and get it to seat in the groove and I can also see the groove side walls move in protest. I could sand/plane this and get a snug fit if I had to.

|

| 6mm fits |

I planed the edges with two shallow runs and it fit. Self supporting but just a wee bit too snug. It would be a PITA fighting this to seat in the groove during glue up. I want a snug but a slip fit also.

|

| LV plow plane |

I have a 6mm iron and the fit is tight. I could get it seated but at the risk of snapping off a groove wall. A quick sand with 120 and I got a slip fit that was also self supporting.

I was thinking of using solid wood panels but I like plywood better. I don't have to worry about panels expanding and contracting with it. I am going to use 6mm Birch plywood from Woodcraft. I can order a 30"x24" piece for about $40 delivered. Or I can drive to Walpole and buy it direct. That outcome depends upon how impatient I get.

|

| 6mm groove, 6mm plywood |

I am planning on painting this cabinet so plywood is a good choice. Next headache is how to join the stiles and rails. That determines how the groove for the plywood panels will be done. Self supporting and kind of easily fitted to the groove. I should be ok inserting the panels during glue up without wanting to give anything free flying lessons.

With mortise and tenon joints I can plow straight through both the stiles and rails. If I use dowels or splines, I can't do that. I'm leaning towards dowels but I am banging around ideas in the brain buckets for how to plow the grooves.

|

| first change |

The overall height of the cabinet minus the base will be about 53". I can't buy a 4x8 foot panel of 6mm plywood. If I add a couple of rails towards the top I can do. Woodcraft sells 6mm in 30x24 inches panels. I like this look even more than just having the lone center stile. This gives it more a craftsman flavor/look.

|

| ouch |

Got my 7 Stanley posters from the Frame It shop. Each one is matted, mounted, and behind conservation glass. A wee bit expensive at roughly $70 each. Sure glad I had the $$$ set aside for it although I had only budgeted $60 per frame.

Don't know where these will go. I don't see any where in the shop to hang them. I could hang them in the boneyard but I would rather have them in shop so I can see them. Another project that will can wait.

|

| exit end |

Switching back to maybe using solid wood panels. My panel raising plane makes a profile that I like but it doesn't have a depth stop. It will bottom out but it will also keep on making shavings depending upon its attitude. I thought I was doing good developing this profile but the tongue ended up too thin.

|

| entry end - 3rd try |

The entry end is ok but not as snug of a fit as I would like. This is a classic headache for me with wooden profiling planes. I tend to be a bit heavy handed on the exit end of the planing run (tapered). It is just a matter of practice and time to master this and get a flat even profile from entry to exit end. I had this problem when I started using rabbeting planes. It took a while but I eventually mastered them. The downside is there is a lot of wasted scrap wood practicing.

|

| yikes |

This is how much of a heavy hand on the exit of the plane run I did. I don't know of anyway to correct this because there is no more wood to remove to fix it. This effectively killed raised panels for the cabinet. I have two other panel raising planes that I don't have this problem with. However, the size of the field (the slope) is only 1" for one and 1 1/8" for the other. Both are too small IMO for this cabinet.

|

| see the line? |

To the left of it is what I shaved and it shows. I got one coat of shellac already on it and it still popped. It is going to take 3 or more coats to cover it. On the plus side the lid still slid in/out easily with two coats of shellac.

|

| dowel experiment |

The outside stiles and top rails are 3" wide. The center stile and inside rails will be 2 to 2 1/2" wide. I like the fact that I can get four dowels at each joint. That will make it stronger with more dowels. Using wide stile and rails because the sides and back need to strong/stiff enough to hang the door from them.

|

| dowel spacing |

The two end dowels are slightly off - the top has a bit more real estate. As long as I pay attention to my mating faces I should be ok with this. This is something that usually bites me on the arse and draws blood.

|

| my new back door |

I like the look of this divided light. I am thinking of using this for the divided light door on the cabinet. The opposite side is the same. I'm not sure that I'll be able to do that though. The cabinet door is 3/4" thick and my back door is 1 3/8" thick.

accidental woodworker

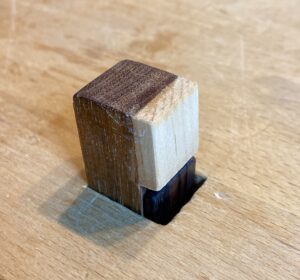

Tabletop Wooden Plaques

This is probably the piece I’m most proud of.

Everything about it is honest and natural. The black comes from milk paint. The finish is nothing more than natural oils and beeswax, rubbed in by hand.

Every part of it was shaped by a real person, not a machine.

Even the camera couldn’t capture its true beauty.

In today’s world, how often do you come across something made slowly, by hand, with love?

This isn’t just an object. It’s a piece of my time, my care, my soul.

It’s priceless. The kind of thing you give to someone you love, someone priceless to you.

Because that’s what gives it meaning.

Love. Without that, it’s just wood.

pencil boxes done.....

I got these two done right on time. My wife is going to North Carolina next week and she'll give them to the grandsons then. Wonder if kids in school even use pencils anymore? I found out that they don't teach how to write in cursive. When I went to elementary school my class year was the last one to learn cursive with ink and a pen.

|

| got two on before lunch |

Before I got to the shop today I made a road to Whole Foods to return a cell phone holder to Amazon. I had bought one for a iPhone SE but the phone was 2" longer than the holder. I ordered an iPhone 16 holder after comparing my phone to my wife's. Height and width were the same but the thickness wasn't. My wife's phone is slightly thicker.

That experience went well after I got help doing it. The check in counter said that it wasn't open until 0900. The lady working the self check out area helped me send it back anyway. There was an automated self help way to log it in and send it off. She saved from me having to make a return trip because I didn't see the automated option.

|

| hmm..... (2nd big japanese toolbox) |

I had to use a hammer to get the lid open. The width was good but the ends were the headaches. The left end was a bit too snug and slid in ok but didn't like reversing itself.

|

| done |

The LN 60 1/2 worked a charm shaving both ends. It took 6 tries before the lid closed and opened easily. The lid also fit in either orientation. I had to plane a slight taper on the sliding lock batten so it cleared the side when pushed into place. Shaving the end dropped it a few frog hairs below the top edge of the side.

|

| hmm...... |

I checked the outside and inside for square with each one of these. Surprised to find that all read square no matter where I checked. I did the drill again with Mr Starrett and confirmed the same as the wooden ones. However, the wooden squares were still slightly off 90 when checked with Mr Starrett. I don't understand it and it doesn't change my mind on favoring metal squares.

|

| got 3 on |

I didn't feel or see a difference in brushing this new batch of shellac on (mix with denatured alcohol vice Everclear). The build is different but that is because I mixed a 2 1/2 lb cut instead of my usual 1 1/2 lb cut. I will try to get the 4th and final coat on tonight after dinner. I want to give the shellac as much time to set up and harden as possible before they travel south.

|

| it is mine |

Decided to keep this one for myself. I already have the wooden squares in it and I'll put any other no home tools in it too. The first toolbox I made in this style I gave to my sister Donna for her husband. I told her if she doesn't want it to give to her son Sam. This box will reside in the boneyard.

accidental woodworker

Sharpening – how to keep the expense down

A Funeral Chair in Washington

Hey folks!

I received a letter from Mike in Washington and thought I’d share. He was looking for a pdf. for my Cabinetmaker’s Toolchest project and mentioned he had recently finished making a Funeral Chair following the plans in my book, The Unplugged Woodshop.

Mike used some cherry and red oak with a bit of beech for his project.

I think it turned out great.

Thanks again for sharing this with us!

The post A Funeral Chair in Washington appeared first on The Unplugged Woodshop.

modification done.....

|

| new pencil box lid |

A wee bit too long and too fat on the width. Still a bit apprehensive about the length but not the width. That I planed until I was happy with the wiggle room.

|

| hmm..... |

I have seen several makers of japanese boxes that used this method of battens on the lids. It doesn't lock the lid it just secures it.

|

| finally done |

These lids are continuing to bite me on the arse. It took me 3 tries before I got this fitted. Sigh. It was obvious to me that the more I make of these it ain't getting any easier.

|

| figured it out???? |

You would think having to deal with only 2 fixed battens it would be a no brainer. But I think I might finally understand this. On one end of the lid the fixed batten is short about a 1/4". It is the second one that determines the outcome. I think I've been placing the fixed batten (or the sliding battens) too close to the other end.

With this lid batten method, the 2nd lid batten doesn't butt up against top box batten when it is closed. It was then it dawned on me - I could put the 2nd batten almost anywhere on the lid. Ta Da.....

|

| a fortunate me-steak |

The bottom box was first and the top one second. It was on the 2nd one that on put the 2nd batten on the wrong side of the layout line. This mistake made the placement of the 2nd batten instantly clear. Dare I say that I think I'm finally over the hump on where to place it?

|

| nope |

Pencils fit in the box but not dropping in directly between the battens. If I had made the sides longer it would have made the interior length too big. The pencils fit diagonally with space to spare.

|

| worked well |

I used extra long cocktail toothpicks and a #49 number drill. Picked these because they were round and the others were flat. I put three toothpick nails in each top box batten. None on the bottom - I'm going with just the glue bond.

|

| the layout |

I'm glad I noticed this - the blade guard extends into the bottom and would hit the batteries. I wanted to push them up tight against the back wall but that isn't happening now.

|

| done |

I wanted to put a charger in here but there wasn't enough room . The depth was ok but I couldn't get it and the batteries in the bottom. I picked the box up after it was packed and carried it out to the truck and back down to the shop. The blade and batteries stayed home. I'll have to get by with taking two fully charged batteries to wherever this gets taken.

|

| impatient |

I went to the package store but they didn't have any large bottles of Everclear. Being impatient and needing a fresh batch of shellac, I'm using this alcohol. This is what I used to use to mix shellac before I got hung up on water content. Thinking about that I wonder what 'alcohol' the old masters used? Rum, wine, or some other distilled spirit? From reading recipes from the 17th/18th century they say to mix in spirits. I haven't read anything indicating the old masters were concerned with water in the spirits. I needed a new batch of shellac to apply to the grandson's pencil boxes.

|

| curiosity |

This is shellac is a dark brown with some red. I'm curious as to what it would look like applied to pine. Would it look like a dye? I'm about to find out. I'll have to make a road trip to the paint store and buy some empty quart cans.

|

| another curiosity |

I've had this button lac for 5 years? Bought it and the Maroon shellac above as a sample. Both of these are meant to be used with mahogany, walnut, or cherry but I'm going to try both on pine to see what 'dye' properties they have.

|

| toast |

The drawer where I stow my shellac had these squares in it. I checked everyone of them with the Starrett and all were off square. I know when I made them they were dead nuts on but over time they have drifted off into La La Land. It is because of this that I don't use them. I don't want to be bothered to stop and check that it is square before using them. So far none my metal ones have drifted in the least. However, I don't check these before use, I ass-u-me they maintain square.

accidental woodworker