Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Norse Woodsmith Blog Feeds

My Sakura Journalling Sketchbook

Bass Guitar Build Pt 5

Now is the time to prepare the fretboard (compound radius etc.), install the frets and dress them. This isn’t the most exciting stage of the build but of course frets are pretty essential to any fretted instrument!

Moby Dick Book Box

done......

|

| hmm..... |

Still getting strange patterns. From this I would guess that I have a big hollow.

|

| gone |

This is the look off the 8K water stone. Any evidence of the hollow is history. I was able to get a complete shiny bevel on almost every iron I sharpened.

|

| next iron |

This is the next iron after coming off the 8K water stone. Try as I might, I couldn't get the bevel to be completely shiny R to L. I tried for over 30 minutes wearing out my arms running this iron over the stone. I left as is after saying No Mas.

|

| the iron from above |

The plane spit out full width and length RML shavings on the first try. All 3 of the shavings were a consistent thickness too. It would seem that the shiny bevel R to L doesn't mean diddly squat.

|

| wasn't a fluke |

Backed the iron off a wee bit to get a thinner shaving. All three were the same width, length, and thickness - but this time a wee bit fluffy. The plane spit out these shavings effortlessly. No ragged out or crappy shavings on the R and L shavings - where the cloudy parts of the bevel were.

|

| yikes |

I did this - I had knocked over my coffee cup and it had spilled on the plane. I didn't know it when the spill happened. I found this hiccup later. I'll find out in the coming years if this rust will play havoc with this bevel.

|

| this worked well yesterday |

The clear bucket I soaked the water stones in. The red one contained all the sharpening grit. I don't think I'll need the wooden tray now.

|

| 4 1/2 |

RML shavings spit out perfectly on the first set up. This plane has a 55° frog and I use this one for squirrely grain. I had to fiddle with this one a wee bit. The frog was set forward too much. I wasn't expecting that because all I changed was a different iron. After I reset the frog, I got RML shavings on the 3rd attempt.

|

| #4 iron |

This is what I saw when I made 5 strokes on the 1000 grit water stone. I dropped down to the 220 stone and started again. On that stone I got the same look on the bevel R to L.

|

| off the 8K stone |

I started with 220 then 1K, 4K, finishing with 8K. With each grit I switched to the next one only after the bevel look was consistent R to L.

|

| #3 RML shavings |

This plane was not cooperating. It wouldn't initially make a full width and length shaving on the R or L. After playing with it and giving it a ton of free goofy looks I found the hiccup - the chipbreaker screw was too loose. The iron was shifting slightly as I planed this scrap of pine.

|

| almost see through |

This was the thinnest shavings I could make that were full width, length, and thickness. I made thinner, wispier ones but they weren't full width but I did manage to make them full length.

|

| post lunch stroll time |

Finally got all the irons sharpened. I cleaned up this mess after I got back to the barn.

|

| nope |

I thought I was done but I had one more iron to do. I set it aside for the PM session.

|

| it survived |

I was asked how this stone holder was dealing with the wet environment? No headaches noted so far. I put a couple coats of Total Boat penetrating epoxy finish on it. I used 3/4" exterior grade plywood for the base and pine for the stone stop thingies.

|

| honing jig center wheel |

The wheel on the right is a replacement wheel for comparison. The jig's wheel is the same size as it but lacks the shine of the replacement wheel. Regardless of that, both of them feel the same. The jig wheel looks dull and rough but it isn't. It is baby butt smooth, 360.

|

| done |

This tray is heavy. I would guess that it weighs 5-6 pounds easily. No finish for this but I do have some Total Boat epoxy penetrating finish if I decide to finish it.

|

| hmm...... |

Sawed this corner removing the gap due the miters not being equal. I was thinking of doing the same saw cut on the other 3 corners but nixed that. I'll keep this with just this corner sawn.

|

| glass door cabinet |

This is what I plan on adding to the front of the shelves. 3/4" thick pine with a 1/2 x 1/2 rabbet. It will hide the plywood plies and help stiffen the front of the shelf against sagging. It will allow me solid wood to plane a profile too.

|

| shelf positions |

Decided to go with two, fixed shelves. That will give 3 openings that are roughly 15 1/2" high and about the same depth.

|

| got it today |

I have two more of these to make. Those pics are a little bigger than these and I'll make two and bring them to Maria at the same time. I'll wait until I have all three before hanging them in the back hallway walls.

accidental woodworker

Field Trip

Recently my friend B invited me to accompany him to a day in Waynesboro at the Virginia Institue of Blacksmithing for their “open shop” session during which he was going to fabricate a replacement part for his wood stove. It was a most impressive facility and I am browsing the class schedule to attend some myself.

There were more than a half dozen former and current students ranging from young teen, working with his mom on a project, to geezers like me. They were all working on projects doing broaching, hand forging, power hammering, riveting, plasma cutting, welding and a lot more.

two distractions first.......

|

| yikes |

The platform I made to hold my #8 was starting to separate. I had nailed and glued the 1/4" plywood to the back edge of the platform. Sure glad that I noticed this before the platform dumped the #8 on the deck. This was the first distraction to deal with.

|

| distraction #2 |

This is philippine mahogany left over from something. Just enough to make an open box to hold a water stone. Using water stones is incredibly messy and you have to contain it. That is what I hope to accomplish with this.

|

| the plan |

The 1/8" tongue will be my water stopper. I'm hoping that it will swell and keep the mess inside the box. Not sure how it will go because this wood is dense and heavy. No clue as to whether or not water can soak into it.

|

| oops |

One corner miter will be a wee bit shy. Originally I had planned to rabbet the corners but that would have exposed the groove for the spline. So I switched to mitering the corners but came up a wee bit short. The spline groove will still be hidden and this is a shop project.

|

| dry fit check |

The walls are 3/4" high which should be sufficient. The water stone doesn't need to be soaking in water while it is being used.

|

| survived the glue up |

The dry fit went off without any hiccups but with glue applied it was like I suddenly lost my ability to use my thumbs. Finally got it clamped before the glue flashed off. I will let this cook until tomorrow.

|

| surprise |

I forgot that I had this - the red thing. It is a water pond for water stones that I got in the early 1980's from Lee Valley. I didn't need to make the water stone station that I just glued up.

|

| surprise #2 |

Forgot that I had made this water stone holder too. The original water stone holders finally got flying lessons. They were tippy, fiddly, and a PITA to use. This holder worked a bazillion percent then they ever did, even when brand new.

|

| hmm..... |

The bevel on this iron was 30° and I changed it to 25°. The water stone is 220 and it did a good job reducing the angle. In fact I couldn't see/feel much different between it and the 60 grit sandpaper on the runway.

|

| ??? |

There is a nice shiny bevel around the middle with two dull looking stripes at each end. I seem to get this just about every time with my plane irons. I applied more pressure on the outside edges and nada. I had a consistent burr from R to L and a straight edge laid on the bevel showed no light under it. It doesn't seem to effect making shavings. This is the 8000 grit water stone but this stripe effect shows up on the 220, 1000, and 4000 stones too. Just a '...what is this?....

|

| one more to go |

I didn't know that I had 3 extra LN irons. These will fit in the 4 1/2, 5 1/2, and the 51. The one I'm holding I am pretty sure I sharpened on the diamond stones and it wouldn't make a full width shaving. I'm betting on the water stones to fix that. Fingers crossed and I'll find out in the AM.

|

| the herd is getting lonely |

I hadn't expected this to take this long. These four should go quickly because they only need a touch up.

|

| came today |

Twenty five 1/4-20 wing nuts for $13 and I only need 8 for the pic frame clamps. I also ordered 20 black oxide 1/4-20 wing nuts from Blacksmith bolt. I should have them by friday.

|

| hmm..... |

Beefed it up with a piece of 1/2" plywood this time. I glued and screwed that to back edge of the platform (original was glue and brads). The other one lasted for a couple of years and this one should outlast me. I'll put the #8 in it in the AM.

accidental woodworker

maintenance day......

|

| 60 grit |

I have tried in the past to square or remove nicks from the toes of blades with 300 or 600 grit stones. You are there forever so I started using adhesive backed sanding strips. At first I started with 220 and progressed down to 60 grit. From there I go back up to 80, 120, and 180 before finishing on my diamond stones.

I don't like using a grinder mostly because of I'm not good at it. Practiced on a couple of used up irons and the results weren't pretty. So I stay away from that tool. Then there is the issue with drawing the temper out of the iron. All and all it is safer for me to use sandpaper.

My 'runway' is a synthetic threshold I got from Home Depot. This one I only use one side but my second one I use both sides of it. I should set this one up to be dual sided too. I have stops on it but I found out through use (on the 2nd one) that I don't need them.

|

| clean up |

I use a heat gun to remove the sanding strip and paint thinner to scrap the adhesive off the runway. Splash a little paint thinner on it, wait 10 seconds and you get to scrape up a gooey, sticky glob of adhesive.

|

| Lowes run |

Bought a 2x2 and a 2x4 foot 1/2" birch plywood panels. I made up my mind on the shelves and this is what I'm using. 3 fixed shelves or maybe only two. The bottom shelf is going to be hard to see the back of it, especially the very bottom shelf of the cabinet. I might eliminate that one or put in a 1/2" shelf.

|

| LN 51 iron done |

Off the miter saw jig - rough and ugly looking. Took a while due to having to remove a nice sized chip at the toe. Forgot to snap a before/after pic of that.

|

| dead nuts smooth |

Sharp does cure a lot of ills. This is the same molding that the LN 51 chewed up and destroyed. I tried planing it both ways and both the LN 51 smoothed them both dead nuts.

|

| chip |

The bevel and toe of this looked good and I thought it would be easy peasy to knock out. Instead when I made 4-5 strokes on the runway to establish the look of the bevel, it showed a chip almost dead center on the toe.

|

| woodpecker square |

This square is awesome for checking square on chisels and plane irons. Before I got this trying to check it with my 4" adjustable square was frustrating to say the least. The inside faces on this square are 1/2" wide which allow it to register on the edge of a piece of paper with ease.

|

| almost ready to road test |

This chisel didn't take as long to do as the LN 51 iron. I tried to use this chisel before but set it aside because it wouldn't hold an edge. I'm hoping that with the passage of a few years since then my skill at sharpening as been upped a wee bit.

|

| super clean and smooth |

The chisel worked this 45 better than I remember it working. Sliced through it like a hot knife through a tub of cheap oleo. To prove it wasn't a fluke, I did two more of them with the same results. I don't recall this chisel staying this sharp.

|

| 2nd O1 iron |

5 strokes on the runway and I have a thin ribbon right at the toe that ain't cooperating. It took me over 45 minutes to completely remove it. This was the last O1 I had to sharpen. Tomorrow I'll start on the A2 irons.

|

| finally done |

The toe looks fractured and erose but it isn't. That is the burr on the backside. The burr is consistent in size from the R to the L. This is ready for the diamond stones.

|

| for tomorrow |

It was a few minutes past quitting time so this will get done in the AM. This is my spare iron for the LN 51.

|

| my Makita hand planer |

I broke this out because if I didn't do while I was thinking about it, it would stay in its black hole forgotten for who knows how long. This is bigger than what I remember being. The electrical cord is still in decent shape - supple and without any cracks or nicks.

|

| hmm..... |

This I totally don't recall. I thought I had two thick irons with slots in them. This looks exactly like the blades that are in the WEN hand planer. I'll search You Tube to see if there are any tutorials on blade changes/setting.

accidental woodworker

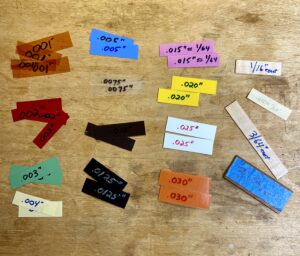

Measure with plastic shim stock

Ladderology 101

On a recent trip to Maryland I needed to address the almost-giant crape myrtle that seems to grow a half-dozen feet a year. It is at that awkward stage, too big to snip from the ground or even a small step ladder, not quite big enough to get from an extension ladder leaning against the house. Using my small extension ladder against the tree trunks is a bit hairy as the ladder rocks back and forth depending on which of my feet is bearing my weight.

Then came a blinding flash of the obvious; what if I create a crook at the top of the ladder so it nestles nicely against the 6-inch trunk, and stays put while I am climbing up or down, or working?

So I pulled out a piece of 1/8″ x 1″ aluminum bar stock from my stash and bent it with just a bench vise and arm power to fit the space above the top rung. 1/8″ x 1″ aluminum is pretty wimpy stuff until you bend it and screw it to a fixed frame, then it gets pretty stout.

Viola! It sits nicely against the trunk, not wobbling back and forth, allowing me to climb, descend and work with my Japanese pruning saw with much greater comfort.

Another win for the blinding flash of the obvious.

glass door cabinet pt XXV..........

At 1238 this PM I officially had adult supervision again. My wife came home after visiting the grandkids in North Carolina. Once I no longer have to babysit Mr Darcy (our male cat) I'll be visiting NC too. As an aside, Mr Darcy did his normal cat routine and treated my wife like she was a stranger. That will learn her for going away without giving him any treats.

|

| the storage part |

I ordered some black oxide 1/4-20 wing nuts from Blacksmith bolt today. McMaster-Carr has brass ones - pkg of 25 for $13 plus S/H. Haven't pulled that trigger yet because Blacksmith bolt had a cheaper price. I have it in the cart so I can indulge myself later.

Made one boo boo with the box. I forgot to center the middle three sided box - it is 1/2" to the left of center.

|

| getting better |

These are Lee Valley clones of Stanley cornering tools. I'm getting better at using them. I'm getting less and less tear out but I still have some. I rounded all 3 edges on the lid moldings and only the top of the bottom molding. No finish for this - yet. But if I change my mind I'll probably slap a few coats of shellac on it.

|

| glazier's points |

These are bigger than I wanted but they are also the smallest ones I could find. Fingers and toes crossed that the paint store has the smaller ones. These will be good for the larger lites due to the thickness of the glass. I think these are too big for the smaller ones though.

|

| hinges |

These are stop hinges and I'm happy with them. I initially thought that they were flimsy but I have used them on several boxes and all of them have withstand the abuse I've heaped on them so far.

|

| hmm..... |

Decided on using a snap catch but I forgot how to do them. It has been a long time since I used this kit.

|

| ta-da |

Figured it out. I eyeballed the snap catch on the box the catches were in. Muscle memory kicked in and I knocked it out easy peasy.

|

| done |

I'm happy with how this turned out. I don't have a warm and fuzzy about the threaded rods but they shouldn't get munged up as is. (fingers crossed)

|

| glass retainers |

Made 6 long ones whereas I only need 4. Started working on the smaller ones for the smaller lites. I need 24 of them.

|

| stockpile |

Made 40 of the smaller ones with one to use as backer when I shoot the miters.

|

| short retainer |

All of the horizontal muntins are the same length. The small vertical muntins are a 1/8" longer than the horizontal ones. I roughed out all of the retainers a wee bit longer than that and I'll fit them individually when the time comes. That will most likely be after I paint the cabinet.

|

| LN side rabbet plane |

Used it to widen the groove so the glass retainers would fit in them.

|

| happy face on |

No light peeking on either leg. Used the 45 clean up jig on the two miters. As an aside, off the miter jig the miters looked ok when I checked them in the lite rabbets.

|

| found it |

I found this molding plane in the boneyard and it is the one I would have used over the one I did. I like this cleaner, simpler look but I would thin the width of the flat above the curved part.

|

| the after pic |

I sawed a 45 on this and it looked like a country lane after a rain storm. This is the look after I cleaned it on the miter jig.

|

| the before pic |

The LN 51 tore this up badly. It looks like slice of swiss cheese now. Happy I was able to clean and smooth it up on the chisel miter jig.

|

| what it is for |

I noticed that when I swing the door shut it flexes. The top and bottom corners move inward. I don't like that because it possibly could crack or break a lite. The first pencil line closest to the front edge is the back side of the door when latched. The 2nd one, furthest from the front edge is where the door stops when latched. I positioned the stop in between the two lines. I secured it with 3 drops of super glue.

|

| done |

I opened and closed the door several times and the stop held secure and the door didn't flex or wobble when it hit the stop. It had a nice secure stop feeling when I shut it. I will put a couple of screws in it later on. For now I want to leave as is and monitor it as I open/close the door.

|

| upcoming maintenance |

The tear out/rough surface I got with the LN 51 was most likely due to it not being sharp (or I was planing against the grain or both). Since I had to sharpen/hone it, I might as well do the other LN planes in the herd. I only have two O1 LN plane irons with the rest of them being A2. A2 sharpens better on water stones so I will break out the waterstones to do the irons. Before that I cleaned up the blades and chipbreakers with mineral spirits. I work mostly in pine and the edges of all of the blades had pine goo on them.

Along with sharpening the blades in the herd I will do the 3 extra LN irons I have at the same time. Added to the plane irons is one 1 1/2" wide firmer chisel. I will attempt to use it to clean the miters on the glass retainers.

|

| my preference |

The O1 LN plane irons are labeled as such with the A2 irons being blank. All of my herd plane irons are A2 and all of their irons are blank - no markings, logos, or writings. I haven't found any LN O1 for sale for years and I check fairly regularly for them. LN stopped making O1 several years ago.

|

| spare LN iron |

I've been pushing this iron up/down the runway for 30 minutes and I've reduced this chip by 80%. I will tackle and finish the remaining 20% in the AM.

Killed the lights and headed topside to chat it up with the wife.

accidental woodworker

glass door cabinet pt XXIV..........

Spent most of the day working on the box for the new picture framing clamps I just bought. I thought I would have gotten that done today but it didn't happen boys and girls. Worked some more on the cabinet and I'm on the fence with the shelves. I think I'm fairly committed to 3 shelves but I'm vacillating about whether to use solid wood or plywood for them. The big concern is solid wood movement vice no movement with plywood. I have the luxury of a few days to wait but I'll have to decide within a couple of days.

|

| 1/4 round molding |

I checked and I can get all 16 short legs out of one molding. I will need two moldings for the 4 long legs of the big lites and one molding for the vertical retainers on the small lites. If I don't screw up I should have almost no waste at all.

|

| I'm getting a headache |

It is looking like the 1/4 round isn't going work. With my spatial abilities swirling around in the toilet trying to orient this in my mind ain't working so well. The miters aren't lining up on this corner. I think I could get it to work if I coped the ends but I haven't ever done coping on such a small molding.

|

| it worked |

The molding is a bit larger (height) than the groove and that allowed me to apply downward pressure to it while I chiseled the miter clean/smooth.

|

| 1/4 round in place |

I don't mind the reveal/margin at the front. What I was concerned with was the molding extending above the muntin bar - it doesn't. It is 3-4 frog hairs below it. However, the miter isn't facing in the direction to pick up the vertical 1/4 round.

|

| happy with this |

I cleaned up both miters in the jig and there is zero light which means the miter is dead nuts on.

|

| the problem |

The moldings aren't uniform which sucks. The left one is fatter than the horizontal one. That hiccup aside, the miters don't line up on either side. I couldn't resolve this hiccup even after giving it my very best goofy looks. Decided to shit can the 1/4 round moldings and go with 1/4" square moldings.

|

| done |

Made a boatload of square moldings. More than enough even if I trip up into a string of oops to deal with. BTW these all came from scraps I was going to shit can.

|

| out of the clamps |

The miters all look decent. There is some glue squeeze out on the toes but they are pretty tight.

|

| L moldings done |

After the square ones were done I made the 1/2" L moldings. I made 6 long ones (27" long) and 4 short end ones.

|

| separated |

I initially wanted to do this on the bandsaw but whacked it out on the tablesaw. It came out a lot cleaner than I expected it to. There are zero fuzzy wuzzies on either the lid of the bottom.

|

| nope |

These are the miters off the jig and although they are ugly looking they are an improvement. I'm still having hiccups sawing the vertical on the miter jigs.

|

| new fence |

I sawed off the original fence on bandsaw and glued on a new one. After the glue has cooked for a couple of hours I will saw new miters and a 90 saw stop.

|

| sigh |

Better but still a degree shy of the exalted 45°. This is why miter shooting jigs were invented for people like me. My shooting jig was off too - it took me 5 plane and checks before Mr Starrett gave his blessing.

|

| yikes |

Noticed this after it had been clamped for several minutes. I had see the toes proud but I canl plane that flush after it has set up. At least this gap will be facing down and won't be readily visible.

|

| dry fitted |

Got a better fit on what is the lid. No gaps on the under side and all the miters are closed up pretty good.

|

| hmm..... |

This was a big surprise. This knurled nut is from the pic frame clamp and I thought it would be metric. After all this is from china but instead of it being a 6mm, it is a 1/4-20 thread. One thing I want to do is get some1/4-20 wings nuts - preferably brass but that will be dependent on the cost.

|

| storage arrangement |

I put 3 'compartments' along the back wall - one at each end and another in the middle. In between them I'll put the 90° corners. The space in front of the 'compartments' will hold the threaded rods.

|

| hmm.... |

This wasn't working. The left end of the bottom one is just plain being ornery. The deeper I planed the profile the more I was ripping out chunks of wood on the left end. The top one I will use on the bottom shelf and the knot will be at the back.

|

| just in case |

Still haven't decide if I'll use fixed shelves or one fixed and two adjustable ones. If I go with the former I'll have the shelf supports ready.

accidental woodworker

glass door cabinet pt XXIII..........

After almost a month of work on the glass door cabinet is winding down. I received the 1/4 round moldings I'm using as glass retainers and the Lee Valley hinges finally came in albeit too late. I have to find some diamond glazier points - I'll try the paint store when I go to pick out a contrasting paint color. Fingers and toes crossed that they will have the ones I want. Painting this is going to be a PITA and I am projecting that it will probably eat up a week plus a few days.

|

| top line |

|

| fill in the old holes |

The dowels I used were a perfect fit. I just had to sand them a wee bit to get a snug fit with the screw hole.

|

| crisis averted |

There was much joy and rejoicing in Mudville. The mighty Ralphie had fixed the faux pas.

|

| close |

I made two more shelf supports. The one above to the right was the first one and I planed that one against the grain. These two don't have to be dead nuts because they aren't married to each other. They will be on opposite sides of the cabinet and impossible to focus on together. Close is good enough and besides most of it will be hidden under the shelf.

|

| Right and Left |

I made a practice cut on the against the grain one to eyeball the angle. I was happy with it and how it looked - this will be somewhat visible and will present a finished end to this shelf support.

|

| WTF? |

I lost one of the moldings I just made. Couldn't remember where I had put it down and I saw it 3 times and didn't recognize as the MIA molding.

|

| found it |

The MIA molding was atop the cabinet and I finally realized it the 4th time I looked at it. I made another one and I had a backup set of shelf supports because I am now leaning toward putting in 3 fixed shelves vice one fixed and two adjustable. It is still subject to change.

|

| shelves |

Flushing and smoothing the shelves. All three were flush on one face but a wee bit proud on the other.

|

| major brain fart |

One shelf is salvageable but the other two are toast. Both of them are short on width. I thought I had made them all an inch longer in both directions. The single one on the right is about a strong 16th short on the width - the depth is over long because I didn't do that one yet. From what I could measure I made these squares - the shelves should have been 16x19 and I made them 16x17. They won't go to waste and I'll use them for some future project.

|

| new toys |

I've wanted to try these clamps forever. Woodcraft has these on sale for 50% off. For the price of one, I got two.

|

| superior tool site |

I wanted everything but the level line sights. $122 shipped to me. If anyone wants the line sights make an offer - the box for them is great shape as is all the others.

|

| hmm.... |

It was advertised that these will clamp 48x48 inches. They do that using a coupler to get the 48" clamp length.

|

| need a box |

Of course I have to make a box to hold all the goodies in one place. 1/2" plywood for the box with a1/4" plywood for the top and bottom.

|

| dry fit |

The miters fitted up good with no gaps. I will saw the lid off after it has been glued and cooked.

|

| glued, clamped, and cooking |

I will let this cook overnight and hopefully I'll finish it by the PM session.

|

| brand new |

There isn't even an errant scratch on it anywhere. This is another curiosity that I needed to have its itch scratched. The box even has the instructions in it.

|

| still readable |

I don't do door butt hinges but it looks like this would do the hinges for the current project. One of the arms has a measurement scale that is dead on accurate. I checked it and was surprised that it was.

|

| doweling jig bushings |

I checked all 5 bushings with the auger bits I have. Only the 1/4" and 5/16" bushings fit the auger bits. The 3/8" kind of fit with the initial lead in tight but once it went in about a 1/4" it turned freely for the rest of it.

|

| L molding |

This is the homemade molding I will use to cover the plywood edges. The plies on this plywood are particularly ugly looking IMO.

|

| WEN hand planer |

The only metal topside on this are the screws that old it together. I

have only used this once without reading the instructions. Still don't

know what some of the 'orange' bits and bobs do. However, I was

impressed and pleasantly surprised by how well this worked flattening a

poplar board.

|

| depth setting |

This worked but I didn't measure how deep it was cutting. I set in at 1/64th because I wasn't sure how well this would perform. I didn't want to over stress it and have it burn out the first time it was let out of the gate. I had played with the two orange turn knobs - I don't what they did and they were hard to turn in either direction.

|

| right, off, left |

This gizmo directs the shavings to the right or left or shuts it off. Don't see what the benefit of that is. It didn't work that well. I had the shavings bag attached and it barely had some dust in it when I finally took it off. I finished the poplar board without the bag and just let the shavings spew out.

|

| the sole |

The sole is aluminum with a V groove on the front shoe. I did see that this is for chamfering but I didn't try that function.

|

| 3 1/4" width |

I bought two sets of replacement blades. I haven't changed these yet and supposedly they no set. I like that because IMO these hand planers can be a bit fiddly when replacing the blades.

|

| thick sole |

The end has a plastic kick stand. The thick sole should stay flat but aluminum can turn gummy and sticky. That can make pushing this hard and cause it stick and stop. That didn't happen on this one use though.

|

| 35 year old Makita |

The blueish case holds my Makita hand planer. I haven't used it a bazillion years because it needs new blades. If memory serves me the ones on it are nicked pretty bad. This planer was a PITA (for me) to set new blades based on the one time I did it. I'll have to open it up and check it out. It has been a long time but my skill set has improved a wee bit since I last used this one.

Only time and use will tell how well the WEN holds up. I think for the infrequent use I plan for it (only to flatten/thickness boards) it should last a few years.

accidental woodworker

Making a Joint Stool from Trees, Part 3: The Seat and the Finish

In my last two posts, I showed how I made the oak framework for my new joint stool, which I’m making with expert guidance from the book Make a Joint Stool from a Tree by Jennie Alexander and Peter Follansbee.

So far I’ve been working oak from logs. But for the seat, I used cherry wood that I also got from a tree.

This cherry tree came down in the back yard of a friend in Alabama during a 2020 hurricane. I hauled off as much of the wood as I could, sawed it up into very rough short boards, and made a bunch of wooden spoons out of it. The rest got stacked up to dry.

Because this joint stool will live in my kitchen, which has cherry wood cabinets and trim, I decided that a cherry seat would complement the space nicely.

Making the Seat

I had originally quarter-sawn a bunch of the cherry logs to about 2″ thick, knowing that they would have plenty of time to dry before I got around to using them. But the top should be much thinner.

The plan was to resaw this little plank on the bandsaw, glue the two pieces together, plane it all down, and end up with about a 3/4″ thick seat.

Resawing a thick plank and gluing the pieces together results in a nicely bookmatched seat.

But if you look closely at the above picture, you can see that the two pieces are not anywhere near the same thickness.

My plan for the seat had gone awry almost immediately. The bandsaw’s blade wandered, leaving one side just shy of 3/4″ thick and the other side well over 1″ thick on one edge. So I needed to remove a lot of material from the face of the thicker piece.

(Side-note: you can see in the background of the picture above that I already have a joint stool, which is a modern reproduction of the form. I have no idea who made it, but I bought it at an antique shop a few years ago. And while I’m not replicating the existing piece’s dimensions exactly, it’s very nice to have a full-scale model from which to work.)

The fastest way to remove stock is with the coarsest tool. In this case, the coarsest tool turned out to be this hewing hatchet. Its edge is beveled only on one side, and it’s designed for squaring up small timbers.

There’s a specific technique to using it effectively to hew to a line, but I won’t detail that method here since I didn’t pause to take pictures of the whole hewing process.

But as you can see, I was able to knock off enough thickness, and I can handplane the surface down from here.

For heavy stock removal, it’s best to use a handplane with a blade sharpened to a slight curve, or camber. I used my wooden jack plane, whose blade I keep shaped and sharpened for exactly these kinds of jobs.

You can take off a thicker shaving if you plane directly across the grain like this. Just be aware that the edge on the exit-side is going to break off some. If this were going to be the underside of the seat, that wouldn’t matter. But this will be the show-side, so I made sure to plan for a bit of loss in the overall width.

You finish by planing the surface down with the grain.

Thumbnail Profile

Once I had the whole piece glued up and planed down, it was time to add a thumbnail profile around the top edges. I had never done this by hand before, but the book shows how it’s done. It’s a surprisingly simple process, and I will definitely use it again on other projects.

Start with the ends. Decide how far in you want your thumbnail. Mark the depth with a cutting gauge or a sharp marking gauge. Clamp a batten across the workpiece in line with your scribed line. Use a saw to cut a very shallow kerf. Just a few light strokes will do.

Now use a rabbet plane to remove the stock. A skew-rabbet like the one pictured above works best. But I imagine that any rabbet plane or shoulder plane would do a decent job if you were to take a light cut. Fortunately I had picked up a wooden skew rabbet plane at an antique mall a year or two ago. They’re actually fairly common on the secondhand market right now, and unlike a lot of wooden molding planes, they are often in usable shape and can be tuned up pretty easily.

Once you have planed this rabbet onto each end, you can plane the rabbet along the long edges, too. Use the same method, though it’s not necessary to saw the kerf if the grain is fairly straight. Just use the rabbet plane held tight up against the batten. It doesn’t even matter if the rabbets at either end are cut to precisely the same depth. Just adjust your strokes with the rabbet plane to make sure the rabbets meet all the way around.

Now that the the rabbets are formed, you can round over the edges. Again, you start with the ends. Plane a chamfer first. When you’re working on the ends, be sure to skew the plane so as to cut the end-grain cleanly.

Then plane off the two corners of the chamfer. The result will start looking like a round-over.

You can plane the initial chamfer around the whole workpiece first, and then go around and take off the corners on each of the four sides. Or you can just work one side at a time, which is what I’ve done.

You can plane or scrape off any remaining corners if you like. And if you really want the round-over to look round up close, you can sand it down perfectly round. I didn’t, though. It’s enough for me that it looks like a round-over from a distance. I don’t mind feeling facets, and it won’t make any difference when you’re sitting on it.

Attaching the Seat

The book admits that the seat attachment is the most fragile part of the stool. The authors note that antique joint stools are often found with missing or replacement seats. The traditional method was to attach the seat with pegs driven through the seat and into holes in the tops of the legs. Because the holes go into angled legs, the angles create a sort of “dovetail” effect that holds the seat on.

I don’t doubt that the result is good if you do it right, but I also know how much this stool is going to get used, pulled around, and picked up by the top. I think there’s a reason that the seats of these stools don’t always survive. If the tops shrunk or cracked a bit, or if someone pulled up on the seat just a little too hard, the seat could pop right off. Then it would be very difficult to reattach it firmly using the same method.

So I decided to use a method that wasn’t really an option for a 17th-century joiner: wood screws.

I made four brackets out of some oak offcuts from the project.

Because these brackets are on the underside, they didn’t need to look pretty. In fact, there was only one part of these brackets that needed to be precise. Everything else could be shaped quite roughly.

Here’s how I did it:

First, I chose a wood screw, and I cut an offcut into this shape.

The stock is approximately 2″ wide and 1″ thick, and long enough to be cut into a right triangle, but the exact dimensions didn’t matter. As you can see, I cut one end at 45 degrees. If your upper stretchers are consistent in thickness, then you can just cut both ends at 45 degrees. But if the stretchers’ inside faces were left rough, as mine were, then you need to figure out what angle you should cut the other end at. Don’t just assume it will be a perfect 45 degrees.

Fortunately, the angle is easy to establish. You don’t measure it with numbers. You just gauge it with a sliding T-bevel.

Use the sliding T-bevel at approximately the same place you’ll put your bracket. I’m screwing them to the short stretchers on each end. Each bracket’s angle is cut to fit a specific corner. They won’t be interchangeable, so I made and installed them one at a time, so as not to get them mixed up.

Transfer the angle to the bracket, gauging from the 45-degree cut.

Cut to the line you just drew. As you can see, the angle between the seat and the stretcher is not precisely 45 degrees. But this bracket will fit the angle perfectly.

Now to make the inside of the bracket.

Figure out exactly how deep you want the screw to go into the underside of the seat and into the stretcher. Gauge the distance using the screw itself. Make sure the screw will penetrate the wood enough to hold it securely but not so far that it pokes through the side or the top. Be sure to account for the whole length of the screw, including the head, since you will want to countersink the head.

Mark that depth with a marking gauge.

Make a shallow saw cut on each line. You only need to cut as deeply as the screw head is wide, not all the way through to the corner.

Split out the center with a chisel. Working from both sides will get the best result. Why not just saw all the way until the kerfs meet? Because splitting out the stock leaves more of the wood in the corner, resulting in a stronger bracket.

Now drill a pilot hole in each face you just sawed. The pilot hole should be wide enough for the wood screw to pass through easily.

Countersink each hole so the screw head will seat nicely and pull the bracket in tightly.

Set the bracket in place, mark the location of each hole, and drill smaller pilot holes into the seat and side stretcher. Use a drill bit with a depth-stop or some other kind of depth indicator so you don’t drill too deeply or stop drilling too soon.

With the top screwed in place, flip the whole thing over and take a look at your work.

With the joint stool assembled, it’s time to do a final once-over before applying the finish. I used a card scraper to level out a few rough spots and take off stray pencil marks here and there. And of course I signed and dated the underside of the top.

The Big Finish

I applied a couple coats of Danish oil to the whole thing. The Danish oil I use is my own mixture: one part each raw linseed oil, polyurethane, and mineral spirits. I apply a first coat very thoroughly so it saturates the whole surface. I let that sit for 10-15 minutes. Before it becomes tacky, I apply a second coat, ensuring that any spots that look a bit dry get plenty more oil. I let it sit another 10 minutes and wipe off any excess oil.

I let the stool dry in direct sunlight, which both dried the finish and darkened the cherry top.

Should the finish become damaged or worn, I can just apply more, though I haven’t needed to do so with any other piece I’ve used this finish on.

After drying for about a day, the stool is ready to be used.

Immediately after I finished this, I thought to myself: “I want to make another one.”

Bass Guitar Build Pt 4

With the first stages of work completed on the body and neck, they can be joined together and fretboard fitted

glass door cabinet pt XXII..........

|

| 1/4" margin |

The door is resting on the bottom and the plan was to split the margin - 1/8" at the top and bottom. With that decided in the batters box was chopping the gains for the hinges on the cabinet.

|

| top one set |

This one rocked a wee bit and I trimmed and checked until it lay flat and flush.

|

| did this differently |

With past hinge jobs I would knife/mark each hinge at the same time and then chop both of them out. Today I chopped the first one and installed it with one screw. With the top one fixed, I marked/knifed the bottom hinge and then chopped the gain for it. I saw this on a Paul Sellers video and what a game changer.

Usually what happened with the previous method was one of the hinges would be slightly off. I would have to chop the R or L end of the gain a bit more. It didn't happen all the time but the Paul Sellers method avoided those small errors that made me wear my grumpy face.

|

| done |

This had to be the easiest hinge job I have ever done. The door opened and closed sweetly with the cabinet on the workbench.

|

| still swinging freely |

I was half expecting the door to hang a wee bit on the latch side (right) but it didn't.

|

| checking the margins |

The top is tapered - high on the right and smaller on the left. The latch side looks kind of tight in a couple of spots but there is zero binding. I won't have to plane a back bevel on this edge of the door. The bottom margin I'm leaving as is - I don't see any need to go nutso and play with it. The only way to see it clearly is get on your knees.

|

| the bottom |

The bottom has a consistent margin but it is a wee bit smaller than the top one.

|

| shelves |

I am going with 3 shelves. The spacing between them is roughly 12".

|

| 15" x 18" |

I have to glue up to get the dimensions needed for the shelves. Not my favorite way for shelves but I didn't feel like going to Lowes to buy plywood.

|

| done |

Rethinking about how the shelves will be done. I am leaning towards making the middle shelf fixed. Doing that will increase the rigidity of the cabinet.

|

| sigh |

Got the snap latch installed but it isn't even. The left part isn't flush with the keeper on the right. It is enough that it is bugging me and I'll deal with it in the AM. The screws are too long also - they are poking out about a 32nd. Another sin with the screws is they are phillips head. I'll be switching them out for slot head screws but I'll have to buy some bronze paint so they will match the latch.

|

| playing with molders again |

Looking at profiles for the front edge of the shelves. I don't want to leave the front edges squared or rounded off.

|

| shelf support |

I like this profile for the middle shelf support.

|

| contender |

This is a window sash plane and it is one of two. From my understanding these came in pairs with #1 used first and #2 next for cleaning and smoothing. I don't have the #2 plane.

|

| my favorite |

This is a Preston plane that was advertised as a profile for shelves and edges. I think I'll use this one because it doesn't take up as much real estate as the previous one does.

accidental woodworker

Livin' la Vida Local - and a Job Opening

If you follow us (@toolsforworkingwood) on Instagram (and please do), you know that we were recently featured in a video made by The Locavore, a NYC company that celebrates local makers and products. We know how hard it is to make a good video, so we are thrilled to have appeared in such a skillful and engaging one.

The Locavore sells a physical guide - you know, a book! - in which we appear. (And not just us. Our friends at W. D. Lockwood Dye have a fabric dye counterpart, Aljo Manufacturing, which also gets the nod.) The Locavore also has a bricks-and-mortar store in Manhattan, located at 434 6th Avenue (W. 10th Street), a few blocks from my old apartment at 6th Ave and W. 12th Street. The store sells products that are grown / baked / fabricated /assembled /crafted /concocted / sewn / stuffed / pickled within 100 miles of NYC.

I visited the store over the weekend. As you could imagine, the vibe is that of a friendly general store, with a range of goods to eat, wear, use to care for your home, or just serve as a cool NYC souvenir. Theres even a bulletin board to keep it really local.

If you live in NYC, are planning to visit NYC, or want to go down that rabbit hole and emerge an hour later, eyes bleary and blinking, check out their website with an interactive map. It makes our large city seem like a series of small towns.

In other news:

We have an opening for a part-time salesperson at our Brooklyn showroom. This time its just for one day/week - Tuesdays.

Sales at Tools for Working Wood is an interesting job. You get a range of customers and that's what makes it interesting. We have people who come in who've been doing this for 40 years and will tell you everything you've ever wanted to know about 80 grit sandpaper. After they leave, you experiment yourself to see if you agree. And then a week later somebody, a newbie, maybe just a newbie in that particular area, will come in and you will get a chance to repeat back everything you've ever wanted to know about 80 grit sandpaper. And frankly this is how we learn. You keep your ears open, you keep your brain functioning, and all interactions are really interesting. Some people come in knowing what they want and some need help. Our goal is to point people in the right direction - and as many customers can attest, even if that direction is to a different store or product we don't sell or to the bad news that no such tool or process exists (yet). And you meet some interesting people too. We're looking for people who are interested in woodworking even if they're not experts because while we can teach people woodworking we can't teach you enthusiasm. I suppose I should mention the employee discount, which if you're outfitting a shop is not a bad thing to have. The most important thing we are looking for in the candidate gets along with people and a desire to learn.

We haven't posted this job elsewhere yet. We're hoping someone who reads this blog is looking to work in the craft and woodworking industries. So if you are interested in a great opportunity we'd like to talk to you. Send us an email to jobs@toolsforworkingwood.com.

In other, other news:

It's time again for Festool Fest! Our Festool rep and his tent of demo tools will be here on Friday, September 12th and Saturday, September 13th, noon - 3 pm both days. It's a great way to try out the cordless table saw, compare sander options or just see all the different tools in action.And of course we will have snacks!

finishing up at the back door.......

I got my Lee Valley order yesterday but no hinges. LV had split my order and the hinges were in the 2nd half. I got the shipping notice from LV but UPS says that they haven't received it yet. If I don't get it by friday it will be early next week. That put a crimp in my plans for finishing up the glass door cabinet.

|

| part of the first Lee Valley order |

All I wanted were the red #2 Robertson drive bits. I had lent my 2" stubby to my wife and she is clueless as to what happened to it. While I was at it I bought a #0 and a #3 driver bit, both I didn't have.

|

| back door |

Got the casings on the door nailed off and up next is dealing with this where the baseboard needs to go. I got two 2x2 foot 1/2" gypsum boards for this. The gypsum board I had is 3/8" and the repair boards had to be 1/2".

|

| half done |

This small job confirmed for me that I hate doing sheet rock repairs. Especially ones at floor level. Working on my knees to do this sucked pond scum. I thought I had some mud but all I could find was the tape. I didn't feel like driving back to Lowes so I'll get a pail of it in the AM.

|

| oops |

Confused myself here - I thought I had to shorten the coat rail by 3/4" because of the hinge side casing. FYI - I didn't have to do that. The coat rail being short by 3/4" but (IMO) doesn't look out of place. Coats will hide the gap and it will look like a board with coat hooks on it.

|

| 2nd choice |

Thinking now of using this instead of the big oval brass knob. If I use the brass knob I will also have to figure out a way to keep the door closed with a magnetic catch or something else. With this one I get a knob to open/close it and also a way to keep it closed.

|

| 3rd choice |

This is the one I think I'm going to use. The 2nd choice lost because I don't have any dark bronze hinges. (I have one but I need two). I get the same benefits and I have hinges that match this finish.

|

| first one done |

This one was a bit fiddly to do. It rocked when I initially checked the fit in the gain.

|

| done |

Just a teeny bit of rocking on this hinge. Both of these hinges have loose pins which I don't like. Mostly because you have to check and make sure that the loose hinge pin end doesn't face the bottom.

accidental woodworker

Two Frames: #270 & #271

Things have been somewhat disorganized in the shop lately! I needed to replicate a previous frame (#256) to send to Diane’s gallery in Carmel to replace a painting sold there, somewhat confusing but it involved a commission Diane received through the gallery so a frame was needed. Diane sent the commissioned painting separately since making the frame required time, it was shipped last week. We are also getting ready to send 9 paintings to her Charleston, SC gallery so I’m busy with the packing of those. In the meantime these are the two frames recently completed.

Frame # 271

This frame is for a 24″ square, stretched canvas for another painting by Diane. The frame is of Basswood and about 3″ wide. I wanted to carve some type of floral design in the corners so searched the internet for it and this is what I came up with. My process is to screen grab and then use the pages program to size the design to fit the frame. The next step is to glue the pattern onto a piece of plastic; salad containers work great! They are flexible and can be flipped over to duplicate the opposite corners.

It may seem like more work than what is needed but for consistency I make a cutting diagram and annotate the exact chisel/gouge used to cut out the design. It helps me to make a left and right side since the design will be flipped and for me it’s real easy to get confused. At the bench I have the pattern clipped to the tool holder, after doing 3 or 4 of them I start to remember which tool to use but at 75 I like having that pattern to keep on track. For me, using specific tools for each curve helps to keep the design consistent. These pictures below show some of the progress, my goal was to have a consistent flow of the design on all sides. This frame started with what I refer to as my 15° profile and has 1/4″ beads that border the carving.

Plow plane for 1/4″ beads

Plow plane for 1/4″ beads

Beginning carve, small tools needed to remove waste

Beginning carve, small tools needed to remove waste

Progress being made

Progress being made

After the basic design had been carved all around the frame it was time to detail it. You can see the original drawing I found was quite detailed with lots of flourishes. Diane’s work is more contemporary so that wouldn’t be appropriate. My take is more modern and “flat”. The finish is Real Milk Paint’s Blue Spruce, top coated with OSMO #3043 satin finish. The picture shows how the top coat really enhances the color and also seals the milk paint. I experimented with the social media “stuff” and created this instagram Reel to show off this frame — Enjoy! You may be prompted to sign in to an Instagram account but if you X out that box the reel should open.

Frame #270

This profile is for a 1/4″ panel so it can be made from material that is 1″+ thick. The width could be whatever you want but I generally stay about 3″ wide. The first step is to cut a 1/4″ bead on the outside edge which, cut #3. You could use a router but I prefer my Veritas small plow plane with a 1/4″ beading bit. Once that’s done use a 1/2″ dado head to make cuts #2. The depth is roughly 5/16″ and the technique is to leave an area wide enough to support the board when using the dado, it will be removed by setting the board on edge against the fence and creating the recess on the face; cut #1. The final table saw work required is cutting the rabbet. Please note: when creating a profile I always cut one or two test pieces about 12″ long for doing the setups. Lay out both ends of the test piece. After each cut is correct I orient the frame pieces the same way and cut them all before going on to the next setup.

Once the profile is cut it needs to be mitered and joined. I use biscuits and allow glue to fully dry overnight. I used a 8/6 mm gouge to form the peas and the tools shown are needed to lay them out evenly on all sides. I did go into quite a bit more detail in my about initially making this frame. Here is a LINK to that one. The finish for this frame is identical to the original #256; composition gold with my Iced Gold finish.

Hope this blog helps any of you who are discovering new ways to make custom, closed corner frames. When I first started writing these many years ago it came about because of the frustration I had then trying to find information about how to do this “stuff”. Appreciate those of you that read this and the occasional comments and question you ask.

Keep making Sawdust (and chips!) — John

glass door cabinet pt XXI..........

Slow day and I didn't get much done. The PM session was a hurry and wait for my annual CPAP check up. Just like the cable company it was I'll be there between 1400 and 1600. I didn't set the world on fire in the AM session either. The House of Glass is still open and still in business. I got 1/8" glass and it was $78 which was twice what I thought it would cost. I had to go back after lunch and pick it up. They don't do wait while they cut anymore.

|

| coat rail |

Scraped it clean and smoothed it out with 40 grit. Happy with how it looks and how it feels. I filled in all the holes with wood putty.

|

| it's gone |

Used the skilsaw to zip off some of the overhang. I am surprised by how smooth of the edge the saw left. The big bonus is there were zero fuzzy wuzzies.

|

| looks better |

The side overhang looks wider than it does on the front. But it isn't - I measured both and there is less than a 32nd difference.

|

| the baseboard |

Three of coats of paint plus one coat (or more) of a clear coat, possibly shellac. This paint/shellac scraped off easily.

|

| from ACE |

I thought I had bought a box of 4d and 6d finish nails. I was wrong and bought two boxes of 4d nails. Which are too thin and too small for nailing the casing to the door jamb. Rather then return the extra 4d box I'll just buy a box of 6d in the AM.

|

| tomorrow's work |

Filled in all the holes and a bunch of divots and ruts. I have to replace a strip of the drywall behind the baseboard. I saw some 2 foot square pieces of drywall at Lowes the other day. I have some at the house (?) that I hope will be enough though.

|

| got it |

I cut my post lunch stroll short so I could go and get the glass and have time to check these before the CPAP rep came. Good fit of the glass in their individual homes, just need to buy some glaziers points to secure them.

The hinges should be coming today according to UPS so maybe I'll get them installed in the AM. Time to start thinking about what will occupy my time in the shop next?

accidental woodworker