Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Be sure to visit the Hand Tool Headlines section - scores of my favorite woodworking blogs in one place.

Elia Bizzari - Hand Tool Woodworking

2026 Chair and Wheelbarrow Classes

I just finished teaching my last class of the year, on 18th Century Chairmaking. A highlight for me was a trip to our local auction house to view a turn-of-the-19th-Century bow back chair made by the McKim Brothers of Richmond, Virginia (photo from the Leland Little website):

The auction-house folks were gracious enough to allow me to trace the very nice, sculptural seat:

I made a copy of the seat during class the next day and intend to offer it as a variation for future students in this 18th Century Chairmaking Class. Teaching this class was fun, and I’m fired up to do it again. Here’s a few classes for next year (there will probably be more next summer and fall, but this is what I’ve got for now):

18th CENTURY LOOP BACK SIDE CHAIR

March 23rd to 28th, 2026 (at my shop)

May 4th to 9th, 2026 (at my shop)

TRADITIONAL WHEELBARROW w/ PETER ROSS & ELIA BIZZARRI

October 5th-10th, 2026 (at my shop)

I’m doing the lottery system again: email me by 8am on Thursday (December 18th) to be entered into the lottery for the class(es) you want. After that, any class opening will be available for purchase through the website shopping cart.

Hope to see you next year!

The post 2026 Chair and Wheelbarrow Classes first appeared on Elia Bizzarri - Hand Tool Woodworking.Chairs for Sale (At a Discount)

I’ve accumulated another attic full of chairs since my previous chair sale four years ago. Many were built in classes – both online and in-person – while others came from changed orders. Most of these chairs are unfinished and can be painted to your specifications. I am offering a discount on them for the month of December. I can ship them anywhere in the US. Details below:

I have three loop back side chairs with baluster turnings that I made in classes that I taught this year. But things don’t always go according to plan in a class: one chair is first-rate, one has a seat that cracked during glue-up and I fixed with glue and three walnut butterflies on the seat bottom, one has a back that’s a few degrees more vertical than the plans call for (not sure how that happened!). The cracked seat is perfectly sound now, and the upright chair is quite comfortable if you like sitting upright. All are ready to be painted to your specifications. $1200 each (usually $1400)

I built this Velda’s chair in my online class with Curtis Buchanan. All the parts are white oak, except a butternut seat: I intended to paint it black-over-red, leaving the butternut seat showing through, but now you get the choice. I don’t have the right photo, so this one of a walnut and butternut version will have to do. $2700 (usually $3000)

A customer ordered four Pete’s Stools, then decided she wanted stools with backs. So I have four Pete’s stools ready for paint. $600 each (usually $700).

I made this birdcage side chair ten or twelve years ago. I put flats on some of the parts, intending to get a decorative painter to do fancy things to it. But the decorative painter disappeared and I threw it in the loft half finished. I finally got the back on it a few weeks ago and it’s ready for paint (but you’re stuck with my limited skills). $1600 (usually $1800)

Reproduction of an early 19th Century writing arm chair in the Dewitt Wallace Museum at Colonial Williamsburg.

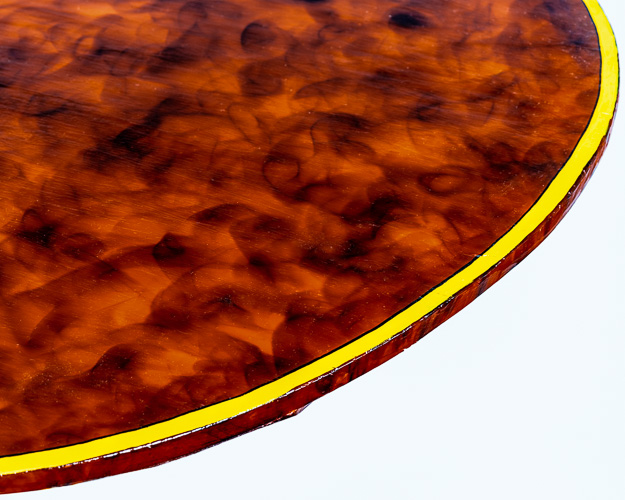

I’ve saved the best for last. This is a copy of a chair in the Colonial Williamsburg collection, attributed to William Challen of Lexington, KY (he was in NY before that, where he has the first known ad for a fancy chair, a style of early 19th. chairs that became intensely popular). Seth and I spent two days measuring the chair, we came home and spent a couple months learning how to build it, then we did a presentation on it at the Working Wood symposium in January 2020. I turned everything on a pole lathe, bored all the holes with spoon bits, then Williamsburg’s conservator Chris Swan spent a couple weeks finishing it with period paints. The black marks are called smoke graining – you hold the chair, painted in half-wet paint, up to a candle and the soot adheres to the paint in swirling clouds. I signed a contract that I would not make any more of these, so this chair is truly unique and will remain so. $5000 (usually $6500)

Rake Tines that Stay (yet are easily replaced)

I’ve been making wooden hay rakes today, which has given me the opportunity to try some new techniques. Here is a short video about making the rake tines using an old method that’s new to me. (Is this is my first foray into vlogging?):

You can watch the Romanian rake maker where I learned this technique here.

The post Rake Tines that Stay (yet are easily replaced) first appeared on Elia Bizzarri - Hand Tool Woodworking.