Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Be sure to visit the Hand Tool Headlines section - scores of my favorite woodworking blogs in one place.

Hand Tools

Investing More – Less Cost

Chairs for Sale (At a Discount)

I’ve accumulated another attic full of chairs since my previous chair sale four years ago. Many were built in classes – both online and in-person – while others came from changed orders. Most of these chairs are unfinished and can be painted to your specifications. I am offering a discount on them for the month of December. I can ship them anywhere in the US. Details below:

I have three loop back side chairs with baluster turnings that I made in classes that I taught this year. But things don’t always go according to plan in a class: one chair is first-rate, one has a seat that cracked during glue-up and I fixed with glue and three walnut butterflies on the seat bottom, one has a back that’s a few degrees more vertical than the plans call for (not sure how that happened!). The cracked seat is perfectly sound now, and the upright chair is quite comfortable if you like sitting upright. All are ready to be painted to your specifications. $1200 each (usually $1400)

I built this Velda’s chair in my online class with Curtis Buchanan. All the parts are white oak, except a butternut seat: I intended to paint it black-over-red, leaving the butternut seat showing through, but now you get the choice. I don’t have the right photo, so this one of a walnut and butternut version will have to do. $2700 (usually $3000)

A customer ordered four Pete’s Stools, then decided she wanted stools with backs. So I have four Pete’s stools ready for paint. $600 each (usually $700).

I made this birdcage side chair ten or twelve years ago. I put flats on some of the parts, intending to get a decorative painter to do fancy things to it. But the decorative painter disappeared and I threw it in the loft half finished. I finally got the back on it a few weeks ago and it’s ready for paint (but you’re stuck with my limited skills). $1600 (usually $1800)

Reproduction of an early 19th Century writing arm chair in the Dewitt Wallace Museum at Colonial Williamsburg.

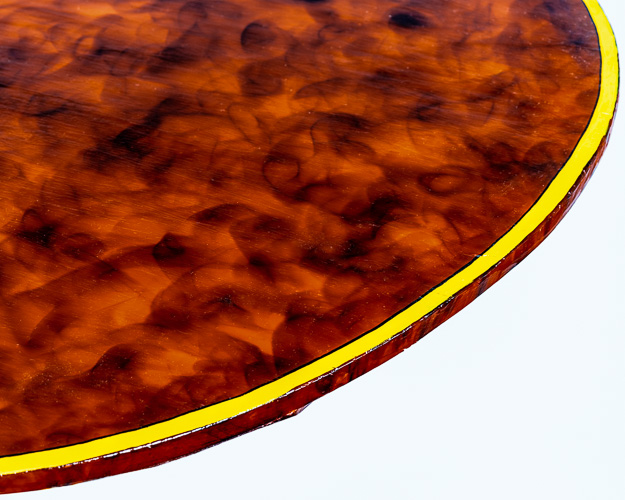

I’ve saved the best for last. This is a copy of a chair in the Colonial Williamsburg collection, attributed to William Challen of Lexington, KY (he was in NY before that, where he has the first known ad for a fancy chair, a style of early 19th. chairs that became intensely popular). Seth and I spent two days measuring the chair, we came home and spent a couple months learning how to build it, then we did a presentation on it at the Working Wood symposium in January 2020. I turned everything on a pole lathe, bored all the holes with spoon bits, then Williamsburg’s conservator Chris Swan spent a couple weeks finishing it with period paints. The black marks are called smoke graining – you hold the chair, painted in half-wet paint, up to a candle and the soot adheres to the paint in swirling clouds. I signed a contract that I would not make any more of these, so this chair is truly unique and will remain so. $5000 (usually $6500)

today sucked........

At 0730 I tried to start my truck to go to the grocery store. The temp was 15 F - 9C then and the truck would not start. It coughed briefly and then the starter continually clicked. The truck had been hard starting for a few days but I assumed it was because of the cold temps lately. The voltage meter on the truck was barely above 10 volts, hadn't noticed before. Not enough to turn the engine over.

A new battery was $161 to replace the one I had bought barely two years ago. The fun part commenced when I removed the old one and put in the new one. There was a shitload of battery acid residue all over the battery terminals and the clamp. Cleaning that up ate up a ton of time and calories.

The fun part was dropping the nuts for the battery clamp. Dropped them twice and both times I had to remove the new battery to find them. Took me over 30 minutes to find the 2nd dropped one. Did I mention that I was doing this in my driveway with the temp at 18F -7.7C. It was #()%&@#)%*#@_)% cold and I was not a happy camper. I had to make a bazillion trips to my shop to get tools - tons of headaches trying to find metric wrenches. Ended up using combination wrenches and slip joint pliers. Eventually I got it done and voltage meter was reading in the normal range.

The truck started up without a whimper several times as I checked it and the voltage meter each time throughout the day. Tomorrow I'm bringing the truck into the shop to have the alternator checked. I want to eliminate that not working at 100%. That was almost 2 hours I'll never get back.

|

| last night after dinner |

Before dinner I had the long and one short glazing bar glued. After dinner I glued on the last one.

|

| 2nd door |

I glued on all three glazing bars on the 2nd door. The doors will be done come the AM.

|

| flushed |

After eyeballing the glazing bars I decided to flush them. The end of one of them got squished a wee bit and that drove flushing them.

|

| hmm...... |

The right hand door tapered gap is the same. I thought that maybe the glazing bars might have been a magic fix.

|

| good sign |

The vertical muntins in spite of the gap, are still aligned L to R and R to L. The left door is snug and the right one also is loose fitting along with having a gap. I need two sets of hinges but that may take a while. A decent hinge set runs about $30 or more. Might have to wait until after xmas before I buy them.

|

| penciling the gap |

The gap at the top is just shy of 3/16". I lined the rule on inboard edge at the top and at a tic mark at 1/8" inboard at the bottom. I want to sneak up on the fit by taking as little as possible off the hinge side of the door.

|

| happy with this |

It took three plane and checks before I was happy with the fit. It isn't perfect but I still have to fit the hinges. They tend to move the door a wee bit and I'll make any final adjustments then.

|

| even gap |

I was glad to see the even gap (top to bottom) on the latch side of both doors. I wasn't sure if correcting for the tapered gap would show up here afterwards.

|

| flushing the tails/pins |

This setup worked well for this planing operation. I had to move it 8 times to plane the corners but no hiccups doing it.

|

| shim glued and cooking |

The first shim I couldn't use because it wasn't wide enough. Didn't notice it when I sawed it out. This one is twice the thickness needed but it gives me a lot of wiggle room for adjusting. It will also be hidden under the door astragal yet to come. Can't think of one that fits in with the overall Shaker look of this bookcase.

|

| base stock |

My original plan was to make this 6 1/2" high but nixed it. That would have used up two 6 foot 1x12's. Instead I made it 4 1/2" high and got it all out of one 6 foot 1x12.

|

| ready for dovetailing |

The four small pieces are the bearers that the carcass will rest on. They are 3/4" x 3/4".

|

| sawing the tails |

Joining the base together with through dovetails. I thought of doing half blinds but went with through. I don't mind the look of seeing the tails and pins.

|

| stayed late |

Tails are done and I got the pins sawn. Stayed in the shop until 1530 to get them to that point. In the AM I'll chop the waste and dry fit the base. I made it a 16th wider and longer for wiggle room. I will cover any gaps with a cove molding.

accidental woodworker

Some shop doings

Every winter there’s a few days it’s too cold to bother trying to heat the shop with my small woodstove. It works out, there’s always some other stuff to do. Today, which started at about 10 degrees F/-12C provides an excellent chance to take a moment to post to this blog. Since the middle of 2023 I’ve mostly concentrated my writing on my substack blog – https://peterfollansbeejoinerswork.substack.com/ which I still think of it as the “new” blog. Here’s some of what’s been going on in my shop lately.

First – a detour related to the cold and the time of year. My wife Maureen and daughter Rose have been knitting & crocheting away and have updated their Etsy site –https://www.etsy.com/shop/MaureensFiberArts

All right, on to the woodworking. A customer ordered a copy-as-close-as-I-can-get of a box at the Metropolitan Museum of Art in New York – and that included a lock with hasp. My friend Mark Atchison finished the lock recently and two days ago I spent time cautiously chopping into the carved box front to house the lock. Whenever I do this, I first cut a practice housing in some scrap.

that gave me enough to go on – and I set out with the carved box front, starting with some depth holes bored with a spoon bit. Most of the modern bits I have include a lead screw that would poke through the board.

From there – chisel work.

I did all the practice, then the real thing, then tested the fit of the lock, turned the key this way & that many times to make sure all was right. Then bored some small pilot holes and clinch-nailed the lock in place.

Boy did that feel good. Every stroke perfect. Centered, tight. Too bad it didn’t work! The test-fits had just enough slop in the fit that the key threw the bolt easily enough. Once it was so tight onto the box front, it was pinched against the housing and there wasn’t enough space to throw the bolt. The key wouldn’t turn. I had to pry those nails out – and today was going to be the necessary trouble-shooting and re-fitting. Now I know what I’m doing tomorrow.

The box itself is a bit different for me – no till for one thing. That makes things easier. No rabbets at the corners – just four boards butted up to each other & nailed. I know many boxes were done that way in 17th century England.

LB carved box begun

LB carved box begun

Most New England examples are rabbeted. I think rabbets help line things up.

This was the first time I’ve done one without rabbets. It was like first riding a bike without training wheels – a bit nerve-wracking.

There’s some ladderback chairs underway, also to fill orders. I finished one of the hickory bark seats last week and have one more to finish off later.

And I took a couple of days out to make some birch-bark containers, something I’ve dabbled in now & then. Anissa Kapsales was here to shoot the process for an article coming up in Fine Woodworking – or is it Fine Bark-working? I don’t know how “fine” my work was, but it was fun…amazing material.

last new project to end 2025......pt V

|

| disappointed |

I paid $60 for this book and it isn't what I thought it was. I expected it to be history of plow plane makers in the United States. Other than a couple of paragraphs on the first page there was no other verbiage on companies making plow planes. However, the book was still an interesting read.

Instead of a history in words, the author did it with pics of plow planes and captions. He did it by state and makers. There were more Rhode Island plow plane makers then I knew. There were 6 of them and I didn't recognize any of the names.

All in all it was a good read - I learned more about plow plane characteristics then I imagined existed. I learned the history of them and the makers in a different way. If I had known this before hand I wouldn't have bought the book.

|

| hmm....... |

I was not expecting the pinch rod to be on the workbench. The opposite diagonal was snug but the pinch rod fit.

|

| square |

The four corners read square with Mr 18" Starrett. The diagonals were off a frog hair over a 16th.

|

| left side door |

This side continues to cooperate - the door fits snug and square.

|

| sigh |

The right side still is acting like the red headed, stuttering step child. As a twist the tapered gap is reversed now. The large end is at the top tapering to nothing at the bottom. I am leaving this as is and I will plane this right door to fit the existing conditions. I'll make up for the gap by gluing a shim on the latch side of the right door.

|

| muntin work |

Started with the left door doing the half lap on the muntin bars.

|

| happy with this |

The half lap is snug and I had to tap it together with a mallet.

|

| glazing bar notch |

I made the notch 1" long. That should be sufficient for anchoring the ends of the glazing bar. It will also be glued to the muntin.

|

| dry fit |

This looks good to my eye. The glazing bar is centered top to bottom and the ends fit snug in their respective notches.

|

| short glazing bars |

I went back and forth on the short glazing bar(s) on whether or not to half lap the long and short bars. I went with two separate short glazing bars. The muntins are 1" wide and are half lapped so that point is secure and strong. The short glazing bars will be secured by the notches and being glued to the muntin bar.

|

| dry fit |

All looks well on the back side of the door. After is glued up I might flush the glazing bars. I kind of like them being proud of the door frame. Right now I'm thinking of chamfering the outside ends and leaving them as is.

|

| hmm...... |

Some router mishap crappola. I plan on leaving the bookcase natural with a shellac finish. Not sure if I'll leave this boo boo or fill them in with a dutchman. It is the back side of the door and won't be seen when the doors are shut.

|

| one down, one to go |

Left door is dry fitted and awaiting glue up. Before I do that I will get the right door dry fitted too.

|

| sigh |

Took one more swipe twice and twice I ended up with the muntin loose fitting. I want and need this muntin to fit snug. I had to make a new muntin to play with. This time I didn't give into making just one more swipe.

|

| ta da |

Three times was the charm. Long muntin fits snug and is self supporting. It even survived me shaking the door like a wild eyed idiot.

|

| right door muntins |

Had to measure for the short muntin. I also placed the doors in the carcass opening to check the alignment of them Left and Right.

|

| if it looks straight...... |

The right door is a few frogs off center on the long muntin. I couldn't see it looking at the doors in place. I was more concerned that the short muntins lined up visually straight across each other.

|

| right one dry fitted |

Doing this went much better than I anticipated it. Other then the long muntin bar boo boo on the right door, everything else went smoothly and fell into place.

|

| partial glue up on the left door |

I glued the left door muntin half lap while I did the right door. I glued the long glazing bar in the notches and glued that to the muntin. I'll do the short glazing bars after dinner. I should be able to get at least one door glued and cooked today.

accidental woodworker

Squares in the shop

Forget “Tiny Houses,” How About A Tiny Shop?

Perhaps because I am lackadaisical about organizing my own living and working spaces I find presentations of exquisite spatial and functional organization to be compelling. This video included ideas I will file away for that “whenever” time that I no longer have the barn space at my fingertips.

last new project to end 2025......pt IV

|

| hmm..... |

This is where I left off with this yesterday. The left door fits snug and square. The right door at the lower right corner isn't square. New battle plan was formed in the brain bucket.

|

| before that battle starts |

Before I forgot to do it again, I did it. I really like these chest handles a lot but they are getting crazy expensive.

|

| toast |

This is the board that I used to drill the shelf pins in the single glass door cabinet. I wanted to use it for this for the two door glass bookcase but not anymore. I'll have to make a new one.

|

| new idea for square |

It dawned on me while eating breakfast that maybe the inside isn't square. I spent all my time and calories trying to get the outside of the carcass square. What is more important to be square is the inside where the doors will be hanging. BTW, I still haven't glued this up - trying to get it square dry first.

|

| found it |

The outside diagonals are less than a 16th off. However, the inside diagonals were a 1/4" off. Problem solved.

|

| big sigh of relief |

Both doors are laying up square on the hinge side. No gaps anymore there but there is one on the joint line where the doors meet. Easier to deal with that gap then the tapered gaps I had yesterday.

|

| glued and cooking |

I used hide glue on this so I would have extra time getting the dovetails seated. The diagonals were both 42 11/16".

|

| scrap board |

Found this in the scrap pile and it is long and wide enough to get the muntins and glazing bars from. I didn't have to use a 6 footer from my Gurney Sawmill stash.

|

| done |

I have to thin the glazing bars, they are too high as is at 3/4". They need to be 5/16". I made one extra long and short muntin board along with 2 extra glazing bars for just in case.

|

| still agree |

I was leaving for my post lunch stroll but before I left I checked the diagonals. I wanted to make sure it hadn't shifted on me.

|

| yikes |

When I got back from the stroll I checked the diagonals again. They had moved 3/16". I used my pinch rods to set the diagonals because I couldn't get a tape reading on the diagonal with the clamp.

|

| double, triple checked it |

I checked it three times to make sure it hadn't moved. I checked it again before I killed the lights. Not sure if this is going to work but I intend to let it cook as is until tomorrow. If it is off I'll try to reverse the hide glue and re do it.

|

| hmm..... |

I was playing around with the muntins and I decided on this placement. I centered the long muntin and placed the short one 8" down from the top.

|

| long one fitted |

The muntin is fitted snug, no glue or any other fasteners. The glazing bar will be glued to the muntin bar which will hold it in place.

|

| half lap |

accidental woodworker

Electric Mandolin Part 3

Here’s the latest video, with the e mando coming together nicely!

Cheers Gary

Why Amateur?

last new project to end 2025......pt III

|

| pin layout |

I knife the tails onto the pin board. I haven't used a pencil for a couple of years now. It seems like every few years I pick up a new method doing dovetails.

|

| the exciting part |

Pins meshing with the tails off the saw. I had to trim one pin on the top board. It was snug but going together. However, it was also splitting the board.

|

| hmm..... |

Not quite what I was expecting on the door fit. The height is about an 1/8" shy but the length is over about the same. I was expecting both measurements to be on the short side.

|

| this is ugly looking |

The carcass is dry fitted and the diagonals were less than a 16th off. This gap is tapered too with it wide at the bottom tapering away to nothing at the top.

|

| fussy time |

Spent some quality time see sawing back and forth trying to get the diagonals to agree dead nuts. I got the back that way but the front I could only manage to get them to less than a 16th

|

| aren't square |

One of the doors is less than a 16th and the other is off by an 8th. But from my way of thinking on it, this isn't enough to cause the gap I have between the carcass and the doors.

|

| Big Red to the rescue |

According to Big Red this door is square all the way around. This is the one that diagonals were off less than a 16th.

|

| hmm...... |

Big Red said the top two corners are square but the bottom two aren't.

|

| head and butt scratching |

I don't understand this headache. I thought that maybe the sides were bowed but they aren't. A straight edge laid on the outside and inside says they are flat and straight. Still have a tapered gap on both doors - the right one a wee bit more than the left one.

|

| planing the doors |

I laid the doors in the opening and penciled a line that I planed down to. I bought this Lee Valley jack plane about 12 years ago to be my main #5 bench plane. But after a couple months I changed my mind. I use it now 99% of time to plane end grain. This plane is phenomenal at planing end grain and the iron edge retention is the best of any plane I own.

|

| hmm...... |

The left door fits in the opening snugly. The tapered gap has shrunk a lot but it is still there.

|

| right side door |

The door is a looser fit then its left side sibling but the ugly, tapered gap is still there. I am at a loss to explain it. The door is square and the carcass inside corners are square - WTF?

|

| door astragal |

I plan on using an astragal to cover the the joint line where the doors meet. It will also serve another purpose. If I have to shim the doors, I can hide the shim under the astragal. This way I won't have to glue one on the hinge side of either door. I think the left door will be ok but I will probably have to add a shim to the right hand drawer.

|

| needs a switch |

Still haven't been able to locate a switch for this router. All I know about it that is it was made in England and no tool repair sites have a switch. All of them list it as without replacement. It wouldn't turn on when plugged in - I thought I had left it hardwired on but I hadn't. I need to rout a rabbet in the doors for the glass.

I've been thinking of buying another router and I'm leaning towards getting a plunge router. But I can't make up mind on cordless or corded. Maybe Santa is listening to me moan about it.

|

| done |

Rabbets routed and the corners squared up. I plan on using flush (to the front) muntins on these doors.

|

| double checking, again |

Big Red says this corner is kind of square. The bottom is square but it runs out with a gap of about a 16th at the top of the blade.

|

| confusing |

This is the back of the carcass and the left side has a gap. 3 corners are square and this one is toast. On the front 3 corners are square with the 4th close but no cigar.

|

| Big Red Says |

Not one photon is leaking by at this corner.

|

| more confusion |

The diagonals at the front are dead nuts the same. Both say 45" outside corner to outside corner. Big Red says the inside corners are square. The left door lays up square and tight on its side but the right still has a tapered gap. I spent my post stroll trying to come up with a reason why it is OTL (out to lunch). Clueless as to why. This will probably change too once I glue the carcass up.

Spent a lot of dead time in the shop cycling through checking the same things over and over and no light bulb came on. It was starting to be frustrating so I killed the lights and left the shop early.

accidental woodworker

Up a side axe size.

I decided to move up a size on the side axe, for these wider panels today. I handled it ages ago, but forgot that I had smoothed the new handle, so I was able to go straight at it.

I was a bit concerned that I had put too much offset into the handle, but it worked beautifully and made short work of rough flattening the board.

Then onto the bench for scrub plane and then jointer.

A stubborn low point persisted; but that's what smoothing planes are for. Lovely big panel.

last new project to end 2025......pt II

|

| yikes |

First day that the temp got below 32F - 0C. I thought it was a wee bit chilly when I went to grocery store this AM. The first day of winter is the 21st, 16 days from now. By 1600 the temp had only zoomed up to 28F - -2.2C. Hope it warms up again to above freezing soon.

|

| hmm...... |

Figuring out the width of the bookcase. As is the board is 11 1/4" wide. There will be a 3/4" back and 3/4" for the doors that will eat up some of the width. That makes the width available at around 9+ inches.

A standard hardcover book is 6" x 9" and it is called an 'octavo'. Most books (hard/soft cover) fall mostly between 5" x 8" to 8.5" x 11". Most of the books I have fall well within these dimensions. This will work for most books and I don't want to glue up stock to make it wider.

|

| reference edge |

Worked on sizing the sides and top and bottom. First batter was getting one edge, flat, square, and straight. This is one of the few time I use my #8.

|

| done |

The width ended up at 11 3/16" which is wider than I expected it to be. Ends are squared off and the length is a 16th under what the width and height of the doors are.

|

| dovetails are in the batter's box |

I always lay out for dovetails the same way. The reference edge becomes the back with the reference face, facing out. I mark the inside with an X and label the corners.

|

| half pins sawn |

Chopping the tail waste. I thought of sawing the waste with a coping saw but nixed it. I like chopping the waste and it is easy and quick in soft pine.

|

| tails done |

I still have to clean the baselines and tomorrow I'll do that before I layout for the pins.

|

| expensive |

Spent about two hours searching the web for these handles. What I find incredibly stupid is that these are sold by the each. I looked at a bazillion sites selling them and not one offered them as a pair. What good is one chest handle? It is like selling a car with only two tires. A point that will drive me to buy these again is that they come with oval head brass screws! I got these from Hardwick & Sons.

|

| what I bought them for |

Haven't given this to my sister yet. Realized moving it around a few times that it is awkward to pick up. Right now it is empty but with stuff in it, it will be even more awkward to pick up and move.

Funny thing happened the other day. My ability to answer comments as R Boumenot is working again. For a couple of years I could only respond to comments anonymously. Another quirk with blogger that has come 360 again.

accidental woodworker

Project End

The creak of the door is slight and the hint of finish lingers, but in the light it somehow feels empty. The tangy smell of fresh cut cherry is gone and the dust that once floated in the air has settled. There is a strangeness to the shop when a project is complete, it is not a feeling of loss, but one that announces change. Lumber that was cut and dimensioned became legs and rails, curves and joints. The bench still holds chisels and saws, a square, and pencil as if misplaced.

Measuring tools are placed in their drawers and chisels at the sharpening station. A brush whisks shavings off the table top while a broom sweeps them into a pan. Soon there are only unsharpened tools, then only a pencil remains.

It’s been a year since the bar stools were complete and many things happened over that time, a trip to Olympic national park, the beginnings of several new projects and of course time with family and friends. Like many bloggers I have gaps in what I post, but I offer no apologies or explanations just thanks for following along and your questions and comments are always welcome. In the next few weeks I will tidy up my half finished notes and send them out, many will not have stories but they are over a year old and I have others to post.

I did want to note the passing of Hobbes (its been well over a year) but as you all know dogs hold a special place in our hearts and he certainly spread his energy (only English Setter owners will fully understand) over 14 years. Run my friend, run……

Fixin’ to Light the Torch

Recently Li’l T got a small rasp and has been going to town carrying it around the house with the rasp and a scrap workpiece from Dada’s latest project. The time has come for Grandpa to think about lighting the torch to be passed to this little guy and his littler brother, Mighty M, who wants to be doing everything his big brother is doing. Littlest brother Wondrous W is only a month old so he is behind the curve for now, as is their cousin Dynamic D who is nine months old. Yeah, walking and talking are helpful in the process.

About 35 years ago I made a pair of half-scale but honest to goodness workbenches for my girls. To that end I recently took Mama’s workbench to live in Dada’s little workshop in the garage for Li’l T amd Mighty M to sue to their hearts content.

This new epoch makes tools a part of the equation for every Christmas and birthday from this point on. Whew.

last new project to end 2025.........

Yesterday I walked my full route and although I finished it, I felt it. My legs hurt a little bit this AM. It took me about 10 minutes longer than it had before I got sick. I had woke up at 0545 this AM but I rolled over and fell back to sleep until after 0700. Today I walked 3/4 of my normal route and I'll keep at that one for a week or so. I didn't think I would need to work back up to what I had been walking.

|

| done |

I got 3 coats of shellac on both of these. The left one I will mail to my sister. The one on the right will live in the boneyard.

|

| last one for 2025 |

I'm not sure what to call this project. It is a bookcase that will have two glass doors. I have enough pine to make this but not for the back. I'll have to make a road trip to Woodcraft in Woburn to buy a couple sheets of 6mm plywood.

|

| stickered |

I picked the flattest boards I had in the stash for the carcass. Top, bottom, and sides being allowed to get any stupid wood tricks out of their system for 24 hours.

I sized the boards so that they were a 16th under the size of the two doors. I would rather deal with the opening being under vice over sized. I haven't decided on a front/back measurement yet. The boards as is are 11 1/4" and my initial choice for the depth is 11". Most books aren't that wide. hmm........

accidental woodworker

Spokeshave work

new project (three drawwer) done.........

The oohs and aahs commenced at 0753. It seemed like it had taken me a bazillion years to finish this. Glad to finally put a check mark in the done column and see what is next in the queue.

|

| glamour pic #1 |

I used a dab of red Lock tite on all 3 drawer knobs. In hindsight this would have presented a little better if the two bottom drawers were half their current heights.

|

| glamour pic #2 |

The dovetails are symmetrical but not evenly spaced. I have wanted to try something like this for a while and I like it.

|

| glamour pic #3 |

All the exterior surfaces are cherry with the exception of the quarter round moldings on the single drawer enclosure.

|

| last glamour pic |

I had to plane the single drawer because it was sticking. I planed the right side top edge and hollowed the back. The drawers aren't a piston fit but when closing the bottom two drawers, air pushes open the non closing drawer.

|

| new one |

My sister got back to me and she said the compartment was too wide - she only had about 1/2" thickness worth of cards. She didn't like the height of it neither. I shortened it on the height and the length.

|

| hmm....... |

Miters first and then do the grooves. I don't have to worry about blowouts planing across the grooves.

|

| shoulda, woulda, coulda, but didn't |

Penciled in the miters and then measured from toe to toe. Got way past the needed 3". I marked and sawed it off at 3 1/4".

|

| dry fit |

Decided to round the front edge. I think based on the scale of this that a rounded front edge will look better than it being squared off.

|

| layout |

This is easy to layout. Extend the center line of the bottom onto the cherry. Put the pencil on one side end point and place the compass point on the cherry board center line. Lay out the arc easy peasy.

|

| not quite half |

I hope this will do what my sister wants it to do. It is hard to tell with her sometimes because she doesn't explain things well. If it isn't I'll make another one and another ....... until I make what she wants.

|

| yikes |

It is 3 frog hairs over 3" wide. On the dry fit it was 3 1/8". I noticed that the miters were not even. That is because the thickness of the back piece isn't the same as the sides. Fingers crossed that the cards my sister has are a few frog hairs shy of 3".

accidental woodworker

Kelmscott Manor